Dairy

Hydroflux Industrial has extensive experience in the design and construction of wastewater treatment plants, hygienic process water, and cow water recovery systems for diaries.

For wastewater Hydroflux has its own range of proprietary equipment including DAF systems, biological treatment designs and sludge handling plant whilst for process water, our designs include membrane filtration, reverse osmosis and more.

With offices located in most major capital cities and full design and construct capabilities, you can be assured of experienced local presence during construction followed by a comprehensive post commissioning support program.

Find out more

The production of dairy products produces a complex, highly variable waste stream, and rarely are any two sites the same. Hydroflux Industrial design and construct customised wastewater solutions for dairies including dissolved air flotation systems with capacities up to 1000 kL per hour as standalone units, biological treatment plants, and handling of the associated sludge.

For trade waste plants for dairies, Hydroflux would typically incorporate balancing of the wastewater followed by a chemically HyDAF system which will generally enable compliance with trade waste discharge requirements. The chemical processes used to enhance the performance can involve one or a combination of acids, coagulants, flocculants whilst waste caustic can also be integrated as a sustainable process.

Anaerobic treatment in the form of high-rate processes or covered anaerobic ponds can also offer cost effective and sustainable solutions.

If the wastewater is being discharged to the environment or being reused, an aerobic biological process is usually required to remove organics and nutrients to suitable levels. Depending on the space available and required output, Hydroflux will design the most suitable solution from its portfolio including SBR, MBR, MBBR and activated sludge processes based on tanks or pond structures.

Dissolved air flotation

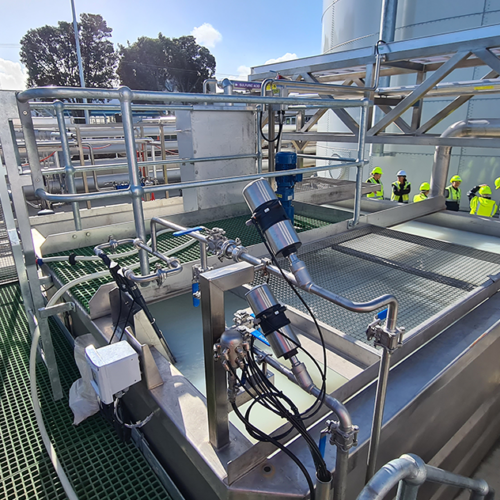

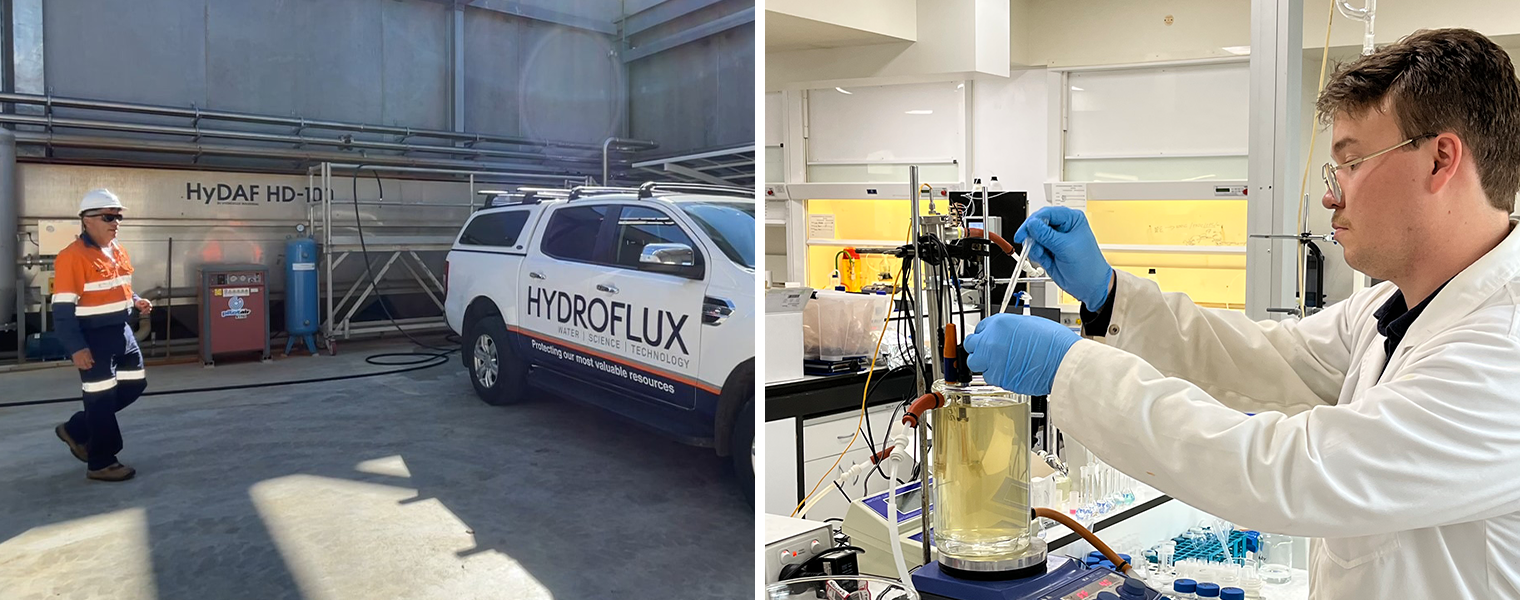

A HyDAF HD-100 installed at a dairy in Sydney. The wastewater is chemically conditioned upstream of the DAF and treated water is directed to the local sewer

The capacity of the balancing facilities, the size and configuration of the DAF, and the chemical program applied to the wastewater will

always depend on type of processing facility and the discharge water quality required, which varies considerably around the regions.

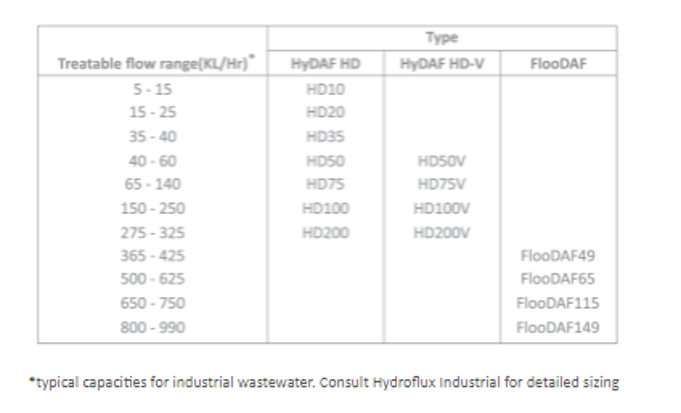

Hydroflux has a comprehensive range of dissolved air flotation models ranging in capacity from 10 kL/hr to 1000 kL/hr so suit any dairy application. The HyDAF dissolved air flotation units are configured with several options to accommodate automated removal of settled sludge and cleaning.

The water quality discharging from the DAF system is a function of the chemistry applied upstream which will typically involve one or a combination of acidification, coagulation and flocculation.

A HyDAF HD-250 operating at a dairy

To ensure optimum performance of the DAF system, Hydroflux uses a flotation engineering tool to match the size of the DAF system to the dissolved air flow to produce a suitable air to solids ratio that will enable solids and grease removal to be maximised in every case.

Biological treatment

If biological treatment is required post DAF it can take the form of high-rate anaerobic processes or covered anaerobic lagoons, or aerobic processes such as MBBR, MBR, activated sludge or SBR.

Hydroflux has expertise in all biological processes and will design the most appropriate system in each case which typically depends on the required performance and available space.

Hydroflux MBBR processes are highly effective in treating wastewater from dairies

Sludge handling

The sludge generated from a DAF system operating at a dairy can be very high in dry solids concentrations and in some cases, adjustments need to be made to fluidise the sludge prior to disposal. That said, depending on the type of dairy, the incoming solids load, and the chemical process applied, dewatering of sludge can be economically viable.

Hydroflux evaluates sludge dewatering on its own merits and will always incorporate the most appropriate sludge handling facilities into the design.

Sludge generated by a HyDAF system treating dairy wastewater. The dry solids concertation of the DAF sludge can often exceed 20%

Process water treatment

The Dairy Industry in Australia is uniquely positioned to lead the food and beverage sector in sustainable water practices. Through innovative approaches, many Dairy sites can become water neutral and in some instances water negative – that is they generate more water than they consume. Through the implementation of sustainable process water technologies, the dairy industry can create enormous benefit to the local community by creating jobs and stimulate the local economies without placing additional pressure on water resources which will become increasingly scarce over the coming decades.

Hydroflux Solutions

Hydroflux have a range of proven, highly efficient process water solutions for the Dairy industry, including:

- Hygienic Cow Water/Condensate Recovery

- CIP Recovery

- Media Filtration & Activated carbon filtration

- UV sterilisation

- Ultrafiltration

- Reverse Osmosis

- Softening/Ion Exchange

- Electrodeionization

Hydroflux design and construct proven and highly efficient process water systems for dairies

Process Water – design and construct solutions

As a specialist in both water and wastewater treatment, our team are uniquely placed to offer complete support for all water services. We understand how process water management impacts on wastewater costs and vice versa. Procurement of water and wastewater projects through a single contractor offers customers significant benefits in terms of management of process risk, as well as cost savings in project delivery, through consolidated design, project management, site supervision and commissioning.

A 250kLD process water treatment plant constructed by Hydroflux incorporating a HyPURE MMF and RO systems

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

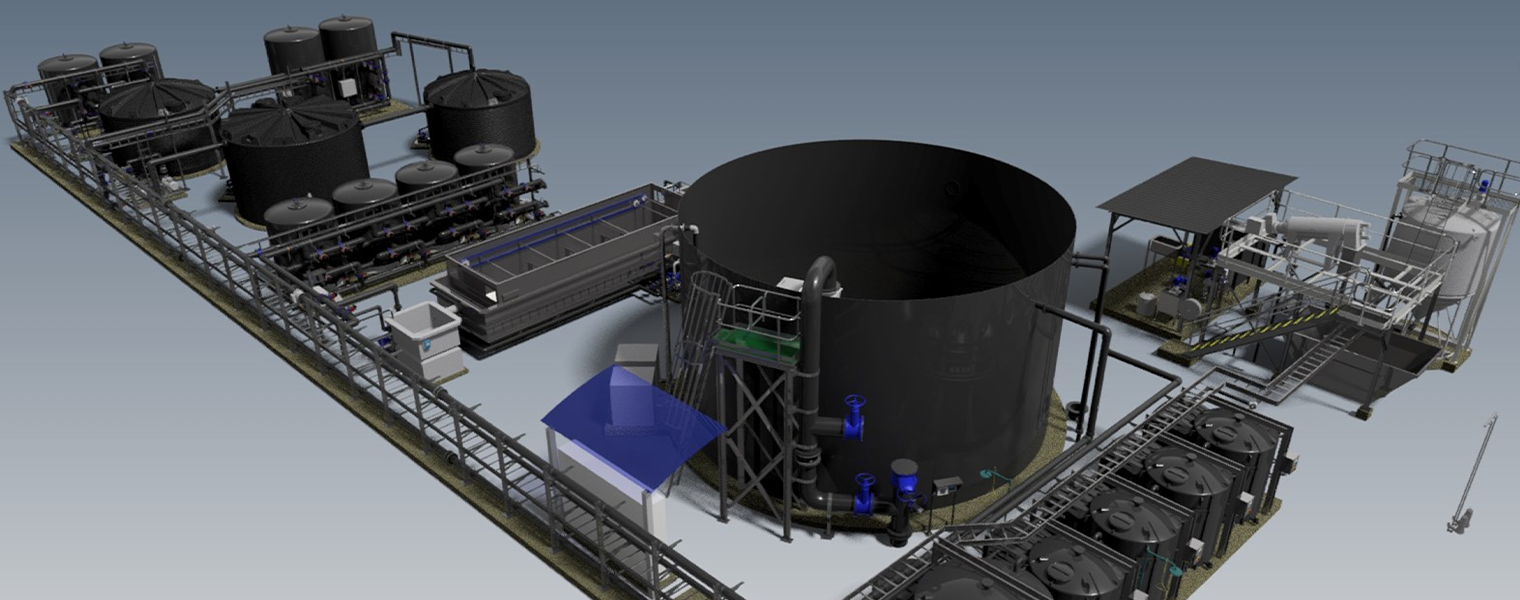

Construction of a turnkey wastewater treatment plant at a new food production facility in SA

Hydroflux can complete all the following works in house which are typically required to construct a process water or wastewater treatment plant

- Process design, development of PID’s and HAZOPS reviews

- Establishment of the most suitable treatment plant layout

- Equipment and component selection

- Civil and building designs including preparation of documentation for council or other regulators

- Electrical design and programming

- Project management and site supervision

- Environmental / Occupational health and safety plans and report

- Quality assurance plans

- Earthworks, civil works, building works, mechanical and electrical installation

- Commissioning, training and documentation as required.

Typical Hydroflux wastewater treatment plant modelling

The utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout Australia.

Hydroflux Utilities provides virtually any form of wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulants, antiscalants, acids/alkalis, oxidizing/reducing agents and other chemicals suitable for conditioning process water feed prior to and after treatment. We also offer a range of proprietary cleaning and sanitizing agents. Our chemists work hand in hand with the project delivery team to develop the most appropriate chemical program tailored specifically to individual sites needs.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the treatment plant so that you can be assured that the system will perform consistently from day one. There are many types of programs available from routine preventative maintenance, periodic

service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.

Biological plant modelling

Hydroflux designs, operates and maintains biological wastewater treatment plants and we are familiar with the many causes of failure and malfunction. Via routine site attendance or online remote monitoring of the biological operating parameters, Hydroflux engineers can predict potential process issues to minimise any impact on the performance of the plant or prevent even problems from happening.

Remote monitoring

Our proprietary HyCONNECT™ remote monitoring system is installed in all our process water plants as standard, enabling instant online technical support and troubleshooting. Specialty solutions are offered for remote locations with reduced cell coverage. No matter where you are, our team of specialists are never more than a phone call away.

HyPURE® Ultrafiltration

The treatment of water and wastewater to meet the high standards for process use or reuse requires the highest grades…

Multimedia Filtration

The HyPURE Multimedia filtration system is a compact, robust and economical solution designed and manufactured by Hydroflux. With nearly 50…

HyPURE® RO Systems

The Hydroflux HyPURE® range of brackish water reverse osmosis systems’ offer high efficiency, a low energy design and exceptional performance…