Planning for Resilience in Biosolids Management– The Role of Thermal Drying

December 3, 2024

Uncertainty around legislative change relating to biosolids management is a key topic for numerous water utilities around the world, in addition to increasing operational costs associated with transport.

In many markets, centralised advanced sludge processing facilities are under construction to exploit the hidden potential of biosolids, whether it’s harvesting energy, producing biochar or generating phosphate rich ash that can be beneficially reused. Others are targeting PFAS removal. Regardless of the process, thermal dryers play a key role in any such advanced biosolids treatment process.

In Belgium, two such centralised facilities are under construction to manage sludge from some forty treatment plants. Aquafin has taken an innovative and collaborative approach with the industry which will provide a significant circular benefit. The dried sludge from the two facilities will be used as a fuel source for a new mono-incineration plant that will be built at the ArcelorMittal Steel Factory. Steam generated by the energy factory will be purchased by the factory.

This partnership will contribute towards Aquafin’s goal of using 100% renewable energy streams by 2030.

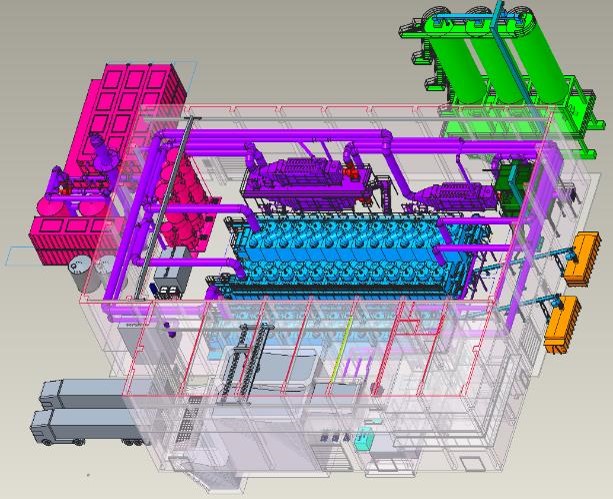

In both projects, HUBER has been contracted to design and build the thermal dryer package using their BT Belt Dryer. A total of five dryers will process 120,000 tons of dewatered sludge per year.

HUBER Sludge Dryer Projects – Some Statistics

- 20+ years of design and operating experience

- Over 90 thermal dryers (Belt and Disc)

- Over 100 solar dryers

- More than 2.5 million tons of sludge processed each year

Hydroflux BT Belt Dryer Projects Under Construction – Australia and New Zealand

- Sydney Project – 18,700 t/a, 90% dry solids

- Wellington Project – 13,950 t/a, 90% dry solids

- Local ANZ team dedicated to thermal drying plants

Drying Solutions – Options

- BT Belt Dryers; full drying

- RotaDry® Disc Dryers; partial drying

- Solstice® Solar Dryers; full drying

- Ancillaries – Control System, Feed Arrangement, Discharge system including cooling screws, conveyors, and dried sludge silos

- Operation and maintenance support

With two major thermal dryer packages under construction for projects in Australia and New Zealand, Hydroflux have built a team that is specifically dedicated to implementing drying technology into municipal wastewater treatment plants.

If you want to learn about how to integrate a thermal dryer into your wastewater treatment plant, or as part of a larger advanced treatment facility, please CLICK HERE for more information or contact us on 1300 417 697.

About the Hydroflux Group

The Hydroflux Group aims to deliver the highest level of engineering and scientific know-how to the emerging issues of sustainability, climate adaptation and environmental protection with a specific focus on water and wastewater.

As part of its vision and mission, Hydroflux has always taken its climate responsibility seriously. In 2022, Hydroflux became Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for its organisation and products. It knows that partnering with customers and clients is the most significant impact it can have in its journey. The Group employs over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands, with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth.

Up Next

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement