Inlet Screens

A Comprehensive Range of Wastewater Screens for Industrial Applications

At Hydroflux, we prioritise effective wastewater screening to ensure optimal treatment by carefully selecting and installing the most suitable screens to minimise the load on downstream processes and protect critical equipment. Hydroflux Industrial offers a comprehensive range of screening systems tailored to specific applications, solids load, solid types, and hydraulic profiles. Hydroflux generally supplies three types of screens designed for effective wastewater management across various industries.

Internally Fed Rotary Screens are the most common type for industrial wastewater treatment, featuring a horizontal basket fitted with wedge wire or mesh, typically ranging from 0.25 to 3 mm in aperture size. These screens are highly effective for handling high-solids and greasy wastewater, making them ideal for applications in the food and beverage industry.

Static Screens, also known as parabolic screens, offer a simple, low-cost solution with no moving parts. Available with various wedge wire apertures, they are best suited for non-greasy applications such as construction wastewater and certain manufacturing processes.

Inground Screens provide an efficient screening solution when the hydraulic profile allows, as they are installed in gravity drainage channels before pump wells. This setup optimises wastewater management by allowing solids to be removed before entering downstream treatment processes.

Internally Fed Rotary Screens

This widely used screen features a horizontal basket fitted with wedge wire or mesh, typically ranging from 0.25 to 2 mm in aperture size for industrial wastewater treatment. It is highly effective for handling high-solids and greasy wastewater, making it ideal for applications in the food and beverage industry. With capacities reaching several kL per hour per unit, it ensures highly efficient wastewater pretreatment.

Features of Internally Fed Rotary Screen

- High Efficiency in Solids Removal: Internally fed rotary screens effectively remove suspended solids, debris, and larger particles from wastewater. The rotating drum design ensures consistent filtration, handling varying particle sizes for reliable and thorough solids removal.

- Compact and Space-Saving: Internally fed rotary screens are designed to be compact, making them ideal for installations with limited space. They integrate easily into existing treatment systems, with drum sizes ranging from 500 mm to 3 m in diameter, allowing for the treatment of several hundred kL/hr in a single unit.

- Self-Cleaning Mechanism: The rotating drum is equipped with high-pressure spray bars, scraper blades, or brushes that automatically remove accumulated solids. This self-cleaning feature reduces labor and maintenance, making the system easier to operate and minimizing downtime.

- Ideal for Greasy Wastewater: When equipped with a hot water or high-pressure cleaning system, internally fed rotary screens can handle high-fat and grease loads, making them an optimal choice for food processing plants and other industries dealing with oily wastewater.

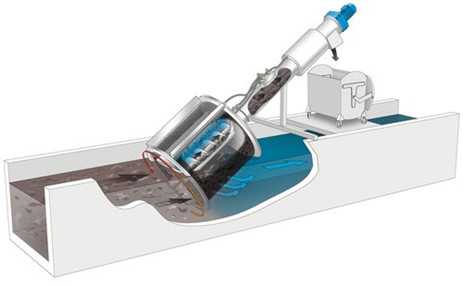

Inground Screens

Inground screens provide an efficient and cost-effective solution for wastewater screening, particularly in applications where the hydraulic profile allows for gravity-driven flow. These screens are usually installed in drainage channels before pump wells, ensuring that solids and debris are removed early in the treatment process.

Features

- Continuous Self-Cleaning – The rotating drum design prevents clogging by continuously removing captured solids from the screen surface

- Fine Screening Capability – Typically designed with perforations or mesh sizes ranging from 0.5 to 6 mm, enabling effective removal of fine solids

- Low Maintenance – Equipped with a simple drive mechanism and minimal moving parts, reducing the need for frequent servicing

- Automatic Solids Removal – The captured solids are typically conveyed via a screw with spray wash system to a collection bin or conveyor

- Corrosion-Resistant Construction – Usually made from stainless steel (304 or 316) for durability in harsh wastewater environments

How the Inground Screen Operates

Wastewater enters through the open end of the inclined screen basket, flowing through the screen while floating and suspended materials are retained by the bars.

As the screen surface becomes blinded, an additional filtering effect is created, allowing the retention of solids smaller than the bar spacing.

When the water level difference upstream and downstream of the screen reaches a certain threshold due to surface blinding, the centrally mounted rake arm begins to rotate. Its tines extend fully through the screen bars, effectively cleaning the basket, removing accumulated screenings, and transferring them into the centrally positioned trough with an integrated screw conveyor.

As the screenings are conveyed and compressed within the inclined pipe, they undergo dewatering and compaction, eliminating odours before being discharged into the customer’s container or a subsequent conveying unit.

Where gravity allows, the inground rotary screen is a reliable, low-maintenance, and space-efficient solution for effective solids separation in wastewater treatment.

Static (Run Down) Screens: Efficient & Low-Maintenance Solid-Liquid Separation

Static or run down screens (sometimes also called parabolic screens) are simple, gravity-fed screening devices used for solid-liquid separation in wastewater treatment and industrial applications. With no moving parts, these screens rely on a sloped, wedge-wire surface to efficiently remove solids while allowing liquids to pass through. Their low-maintenance design, high screening efficiency, and durability make them ideal for applications such as manufacturing, infrastructure, pulp and paper, and mining industries.

Key Features of Static (Run Down) Screens

- No Moving Parts – Operates passively using gravity, reducing mechanical wear and maintenance needs

- Wedge-Wire Screen Design – The precisely spaced wires ensure efficient solid-liquid separation with slot sizes typically ranging from 0.2 to 2 mm

- Energy-Efficient Operation – Requires no external power, making it a cost-effective and environmentally friendly solution

- High Solids Capture Efficiency – Effectively removes suspended solids, reducing the load on downstream treatment processes

- Durable Construction – Typically made from stainless steel (304 or 316), ensuring long-term resistance to corrosion and harsh environments

- Low Maintenance Requirements – Simple design with minimal parts results in easy cleaning and long operational life

Why Choose Hydroflux?

Uncompromising Quality

Hydroflux is dedicated to delivering high-quality, sustainable screening systems and wastewater treatment systems in general with exceptional build standards and efficiency. Our systems are engineered for long-term reliability, ensuring maximum performance while minimising operational and maintenance costs.

Design and Construct capabilities

Hydroflux’s team includes qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians. With offices located across Australia, Hydroflux ensures a strong local presence throughout the duration of every project. All projects are carried out under externally certified occupational health and safety and environmental management systems.

Hydroflux designs and constructs comprehensive wastewater treatment systems that incorporate various types of processing equipment, including screens, physical/chemical, biological, and tertiary treatment technologies to enable high quality discharge or water reuse.

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand market and is also carbon-neutral. Click here to find out what this means for you.