Mining Water Treatment

Tailored Water Treatment Solutions for Mining Operations

For mining operations, water is the most precious commodity and the supply of clean water is critical for essential processes, services, and daily operations. Hydroflux provides customised solutions to address all aspects of a mining operation, including:

- Ground & process water treatment.

- Tailings, wastewater treatment.

- Potable water treatment.

- Sewage wastewater treatment.

- Environmental discharge & regulatory compliance.

- Mine remediation.

- Recycling and Reuse

With extensive experience and expertise, we specialise in developing tailored water and wastewater treatment solutions that address the unique water needs of each mine site and its operations. Our team understands the complexities of water treatment and the unique conditions faced in mining. No operations and processes are identical and as such, we believe in the importance of tailored solutions. We work closely with each operation to develop optimised treatment solutions which are uniquely designed to suit site conditions and operational needs.

View our Mining Sector Photo Gallery below

The Hydroflux team brings decades of experience in water treatment and a deep understanding of the requirements in the mining sector. Our team consists of dedicated project managers, process and mechanical engineers, electrical & automation and technical support engineers. This multidisciplinary approach enables us to offer end-to-end solutions for your project and direct ongoing support with experts who are familiar with your project and requirements.

Scroll down the page or click on the links to go directly to Potable Water Solutions, Sewage Treatment Solutions or our Design and Construct or Support Services

Comprehensive Solutions for Process and Tailings Water Treatment

Over the past decade, the demand for treatment plants capable of producing high-quality treated water for recovery, reuse, and compliant environmental discharge at mine sites has significantly increased, particularly for end-of-life mining operations. Effective treatment of process water and tailings management is essential for minimising environmental impact, ensuring regulatory compliance, and maximising water reuse.

Hydroflux provides comprehensive solutions for process and tailings water treatment, offering turnkey plants and system upgrades that integrate seamlessly with existing infrastructure. Our treatment systems are designed to manage complex challenges, including high suspended solids, heavy metals, sulfates, nitrates, and other contaminants. Recognising that every mining operation is unique, we take a collaborative, tailored approach, leveraging proven technologies to deliver cost-effective, low-maintenance solutions that maximise system performance and availability while meeting stringent environmental standards.

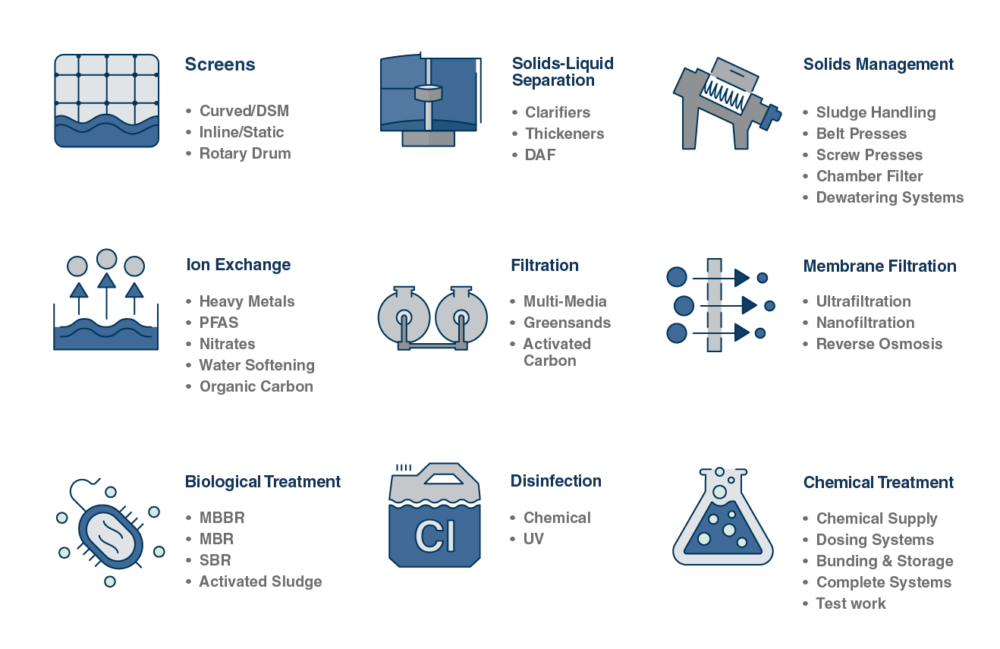

Some of our key processes and technologies include:

Effective water management is essential for the sustainability and operational efficiency of mining projects. Hydroflux is Australia’s leading water treatment company committed to advancing the sustainability of mining operations through innovative water treatment technologies and solutions.

For more information or to discuss your specific requirements, please contact us.

Fully Customised, On-Site Potable Water Treatment Solutions

Potable water is one of the most critical resources on site, supplying drinking water, site amenities, safety equipment, and essential process systems such as safety showers, gland water, and chemical batching. Hydroflux provides fully customised, on-site potable water treatment solutions tailored to the specific water source and site requirements.

Groundwater is a common source for potable water treatment, but its quality varies depending on location and geological conditions. In some areas, high levels of dissolved minerals and salts can result in brackish water, requiring specialised treatment. Hydroflux designs and implements tailored treatment processes to ensure safe, high-quality potable water, typically incorporating the following process elements.

Depending on your water source:

- For high turbidity, the initial stage of treatment will usually involve chemical coagulation followed by clarification. This process aims to remove suspended solids and particles from the water, enhancing its clarity and reducing turbidity.

- For non-brackish water with low levels of dissolved salts, the secondary and final treatment approach involves media filtration followed by disinfection. Media filtration effectively removes impurities and particulate matter from the water, while disinfection destroys harmful microorganisms, ensuring the production of potable water.

- For brackish water, a popular method of treatment is the utilisation of reverse osmosis (RO). This involves passing the brackish water through a semi-permeable membrane to effectively remove dissolved solids and salts. Reverse osmosis is highly efficient, capable of removing up to 99% of salts and minerals present in brackish water. Hydroflux can also incorporate Ion Exchange technology for similar purposes, utilising a resin bed that facilitates the exchange of ions.

To simplify installation and operations, Hydroflux provides containerised and skid-mounted solutions. These compact, pre-engineered systems are designed for rapid deployment, making them ideal for remote locations with limited infrastructure. Their modular design allows for easy transportation, minimal on-site assembly, and seamless integration with existing water supply networks.

Please view the animation of a containerised RO system for more details.

For more information on our potable water treatment solutions or to discuss your specific requirements, please contact us

Decades of Expertise in Mining Sewage Treatment

Most mines are located in remote areas with extreme conditions, sensitive environments, and shared water resources. Wastewater treatment for onsite facilities and camps must be efficient, adaptable to fluctuating water supplies and varying contaminants, and designed to support ecological restoration and monitoring, and in many operations, treated effluent is also required for reuse in onsite amenities.

With over 60 years of experience, Hydroflux has been at the forefront of designing, developing, and supplying advanced wastewater treatment plants for the mining sector. The Hydroflux RoadTrain activated sludge plant is a highly robust and easy-to-operate system, specifically engineered for remote operations. Its customisable design allows it to meet diverse capacity requirements, site conditions, and local water supply variations, ensuring reliable and efficient wastewater management even in the most challenging environments.

A Proven Track Record Since the 1960s

The RoadTrain has been a trusted wastewater treatment solution in the mining industry since the 1960s. Upgraded versions continue to be supplied today, remaining a preferred choice among clients due to their scalability and adaptability. One notable installation was at the Bowen Basin coal mine in central Queensland during the 1970s. Initially designed for 400 people, the system underwent multiple relocations and upgrades, eventually accommodating up to 800 people by 2012.

Today, the RoadTrain range includes various options, from standard activated sludge treatment to advanced nutrient removal systems.

Prefabricated, Flat-Pack Systems for Remote Sites

The RoadTrain has also been engineered as a prefabricated system that can be easily bolted onto a concrete slab. Delivered in a flat-pack format, this innovative design minimises logistical challenges for remote sites with limited road access or no crane availability. This approach was successfully implemented in 2015 at Moro Village within the Oil Search mining lease in Papua New Guinea’s Southern Highlands, where a bolted RoadTrain was installed under demanding conditions.

For more information or to discuss your specific requirements, please contact us

Hydroflux: Delivering Tailored Engineering Solutions with Uncompromising Standards

Hydroflux specialises in integrating our high standards for system design and safety with site-specific engineering requirements, prioritising our customers’ requirements above all else. This commitment ensures that each project achieves the best possible outcome. We pride ourselves having dedicated inhouse teams across our offices, including:

Our inhouse capabilities uniquely position us to take your project from design right through to installation, commissioning, and provide continued technical support and chemical supply. Each team and department is closely integrated, providing full understanding of design impacts on process efficiency, CAPEX and OPEX costs for each operation. Our familiarisation and experience with mine spec standards including safety, civil, mechanical, electrical, instrumentation and automation means we produce a compliant and optimsed design from the start of the project.

Complete Compliant and Optimsed Design Packages

For each project, our experienced team also provides assistance with:

- Process Design, PFD & PID

- HAZOP reviews & workshops

- On going technical support

- All process equipment and component selection

- Installation (mechanical & electrical)

- Chemical, consumables & spares supply & support

- Plant layout designs

- Documentation for compliance or regulatory bodies

- Civil & building works and designs

- Quality assurance plans

- Electrical design and automation

- Commissioning & site supervision

- Environmental plans and reports

- WHS plans and reports

- Project management

- Technical workshops, virtual and onsite training

Below are 3D drawings of a wastewater treatment plants recently constructed by Hydroflux incorporating a range of proprietary equipment

f

Certified WHS, Environmental and Risk Management Systems for Peace of Mind

With a team of qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians, Hydroflux offers flexible contract options, ranging from equipment design and supply to full turnkey installations with expert execution at every stage. All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Our offices across Australia provide a strong local presence, ensuring seamless project management from design through to installation. Additionally, Hydroflux offers post-installation routine service contracts to maintain system performance and longevity.

Comprehensive Support for Water & Wastewater Treatment Plants at Mine Sites

Hydroflux is a trusted partner for the mining industry, providing end-to-end water and wastewater treatment solutions. Beyond system design and installation, Hydroflux offers chemical optimisation, preventative maintenance, biological plant modelling, and remote monitoring, ensuring long-term reliability and performance for every plant.

Chemical Optimisation

Hydroflux offers a comprehensive range of chemical solutions, including coagulants, antiscalants, acids/alkalis, oxidising/reducing agents, and proprietary cleaning and sanitising products. These chemicals are formulated to optimise process water feed conditioning before and after treatment, or enhancing the performance of your wastewater treatment plant. Our chemists work closely with the project delivery team to develop a site-specific chemical program that ensures maximum treatment efficiency and cost-effectiveness.

Preventative Maintenance & Service

To guarantee consistent performance from day one, Hydroflux provides customised service and maintenance programs. Our engineers and technicians discuss preventative maintenance strategies during the construction phase, offering routine service, periodic overhauls, and full plant operation support. Our service team is available 24/7 to respond to unforeseen breakdowns, ensuring uninterrupted plant operation.

Remote Monitoring

All Hydroflux process water treatment plants come equipped with our proprietary HyCONNECT™ remote monitoring system, providing instant online technical support and troubleshooting. For remote locations with limited connectivity, we offer specialty monitoring solutions to ensure continuous system oversight. No matter where your facility is located, Hydroflux specialists are just a call away, ready to assist with real-time diagnostics and performance optimisation.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the ANZ-Pacific market and is also carbon-neutral. Click here to find out what this means for you.