Design and Construct

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

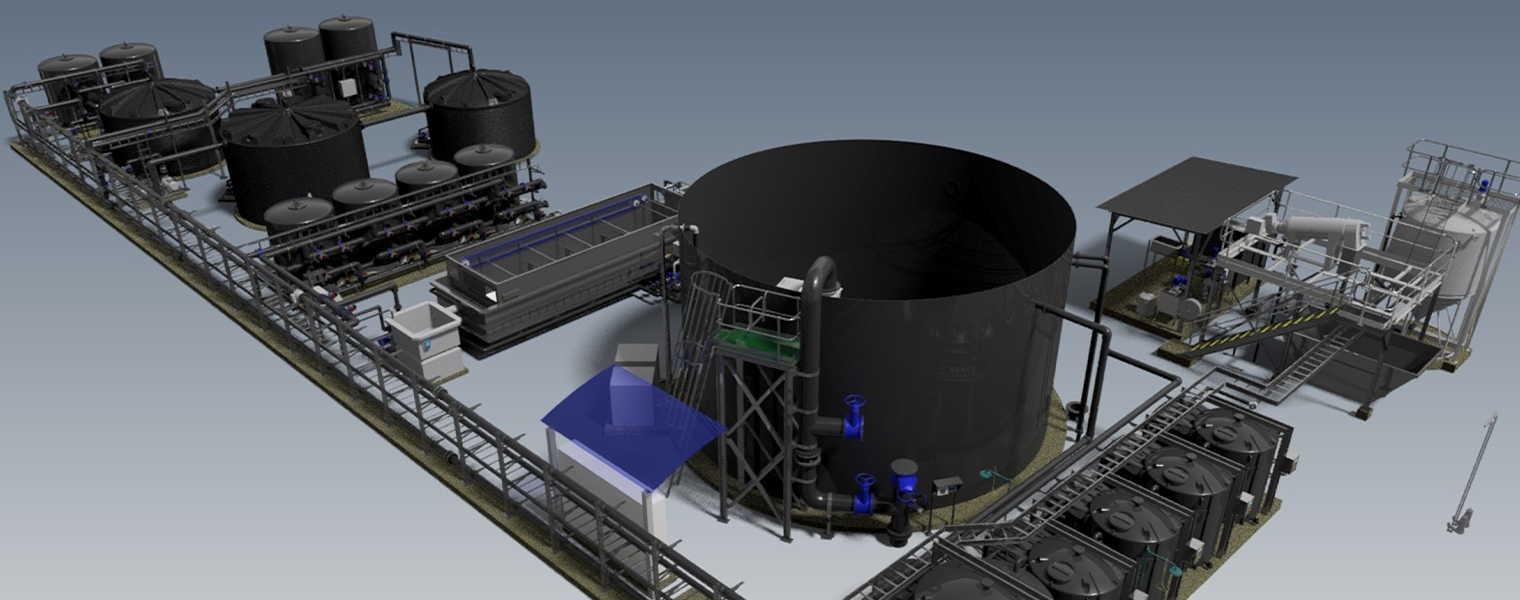

Hydroflux design capabilities include all those necessary to conduct a complete turnkey design and construct contract.

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

Find out more

Hydroflux conducts many levels of design from feasibility through concept to construction. Designs for water and wastewater treatment plants will often include several or all of the following:

- Process design, development of PID’s and HAZOP reviews

- Dangerous goods storage and handling

- Hazardous area assessment

- Odour modelling and control

- Water testing and analysis

- Biological treatment plant modelling using BIOWIN software

- Establishment of the most suitable wastewater treatment plant layout

- Equipment and component selection

- Geotechnical studies, civil and building design

- Preparation of documentation for council and other regulators

- Electrical design, programming and SCADA

To allow better collaboration with other project stakeholders during the design stages and improve efficiencies during fabrication and installation, Hydroflux uses Autodesk inventor 3D as its main model authoring software.

Hydroflux speciality is turnkey design and construction contracts which often benefit from the incorporation of proprietary Hydroflux process equipment. Our project managers are locally based and experienced in all works associated with the construction of an industrial water or wastewater treatment project.

Hydroflux Industrial conducts all projects under externally approved management systems and is Australia’s first Water-tech company to achieve Climate Active certifications. This means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

Construction of the water or wastewater treatment plant will often include several or all of the following:

- Safety in Design, including design and installation of safe systems of work for operations

- Verified carbon footprint calculations

- Environmental plans and reports

- Quality assurance plans

- Provision of all equipment datasheets and drawings

- Supply, factory test and deliver all mechanical, electrical and control equipment necessary to achieve the scope of works, and design intent

- Transport, unloading, storage and preservation of all equipment from the place of manufacture to site

- Carry out all civil works, building works, and mechanical and electrical installation required for complete construction

- Construction verification, commissioning and handover of the plant.

- Certificates and licences as required.

- Operation and Maintenance manuals and as-built plant drawings and schematics

The Hydroflux Utilities division provides the link to integrating the Hydroflux® businesses by providing a comprehensive support network for customers throughout Australia.

Hydroflux Utilities has a team of service engineers and technicians available nationwide .

- Chemical supply

- Process optimisation

- Preventative maintenance

- Service contracts

- Operation contracts

- Remote monitoring and control

- Treatment plant modelling

Hydroflux Utilities provides virtually any form of wastewater management programs including:

Chemical optimisation

Hydroflux has a comprehensive range of coagulant and flocculants suitable for conditioning water, wastewater or sludge. The most appropriate chemical program will be determined before commissioning based on experience, or test work if possible and continuously reviewed during operation. Lng-term cost-effective chemical supply contracts can be arranged.

Preventative maintenance and service

Our engineers and technicians will discuss service and maintenance programs with you during construction of the treatment plant so that you can be assured that the system will perform consistently from day one. There are many types of programs available from routine preventative maintenance, periodic service and overhauls, to complete plant operation. Our technicians are available 24/7 to attend to unforeseen breakdowns.

Biological plant modelling and remote monitoring

Hydroflux designs, operates and maintains biological wastewater treatment plants and we are familiar with the many causes of their failure or malfunction. Via routine site attendance or online remote monitoring of the biological operating parameters, Hydroflux engineers can predict potential process issues to minimise any impact on the performance of the plant, or prevent even problems from happening.