Dewatering – Design and Construct

Hydroflux is proud to be Australia’s first water treatment and technology company to achieve Climate Active carbon neutral certification for our entire organization. As part of our climate change mission, we continue to research, develop and invest in sustainable technologies.

Now our journey continues – our main range of water technology and associated chemical products are Climate Active certified as carbon neutral. To read more on our journey, click HERE

Whether the most suitable sludge dewatering technology for your application is a screw press, CakeMax® filter press, belt press or centrifuge, Hydroflux has the knowledge and experience to design and construct a complete sludge dewatering and solids handling plant to meet your requirements.

We have installed sludge dewatering plants to dewater primary sludge, biological sludge or combined sludge generated from the treatment of wastewater across a wide variety of industry sectors including:

- All types of food processing plants from meat works to dairies and breweries to rendering

- Hydroxide sludges from ground water treatment plants and metal processing facilities

- Construction sites to dewater construction slurries and sludge generated from the treatment of ground water

- Anaerobic lagoons, aerobic and facultative ponds

Find out more

Hydroflux will design the complete dewatering system using the most suitable process taking into consideration volumes of slurry to be processed, feed solids concentrations, ease of operation and performance of the dewatering plant

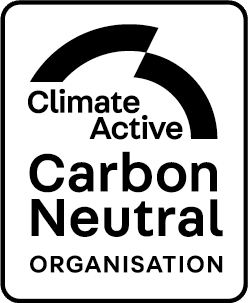

Dewatering equipment can be mounted on platforms allowing the dewatered cake to drop into a skip, bin or bunker as is shown in the CakeMax® filter press example above on a construction site.

As well as selecting the most appropriate dewatering process, we will design and construct the complete dewatering system can involve several or all of the following:

- Slurry storage and blending facilities

- Dosing equipment for chemical flocculation and other chemical conditioning as required

- Platforms and conveyors to transport the dewatered cake into bins, bunkers or trailers as based on volumes and logistics

- Control systems and integration in BMS

a Q280 unit dewatering primary DAF sludge at a rate of 1.5 kL/hr

A common configuration for smaller industrial projects involves mounting the dewatering unit at ground level and using one or a series of conveyors to transport the dewatered cake into a suitable bin.

A small screw press being used to dewater DAF sludge at a food and beverage facility in QLD

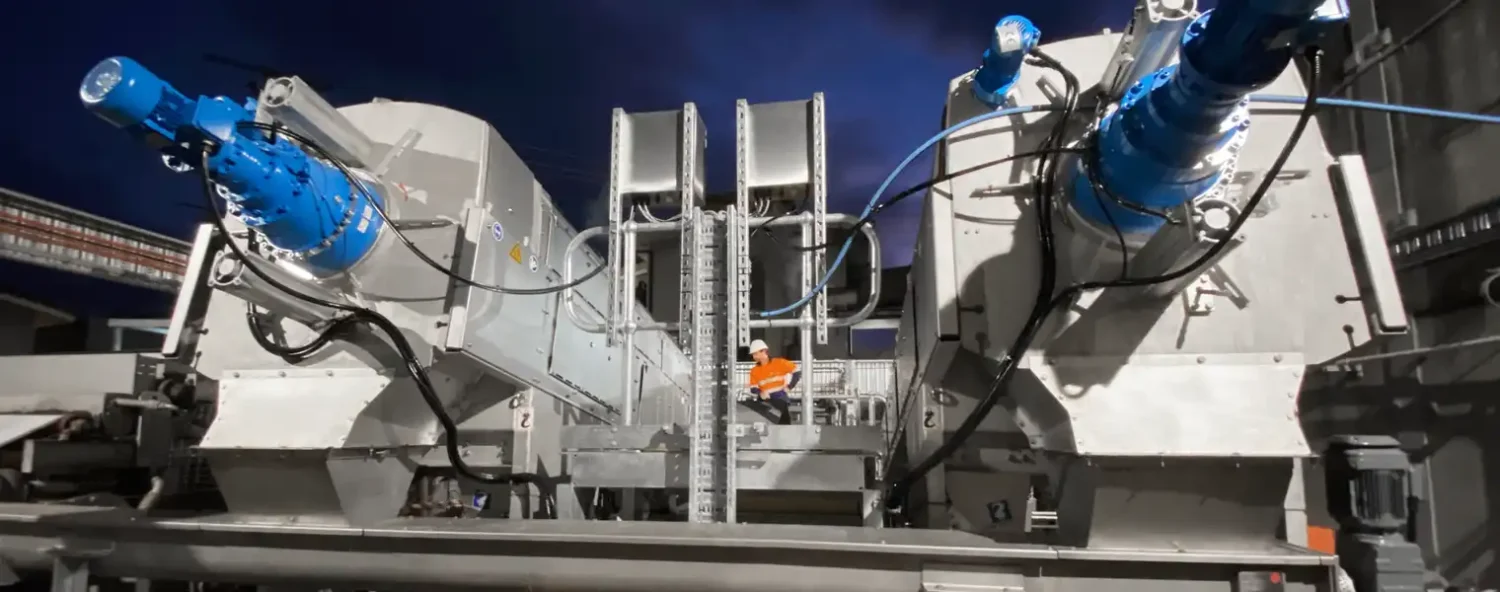

For larger applications such as dewatering of waste activated sludge Hydroflux will typically design the system based on the use of multiple units discharging into common conveyors.

What is the best type of dewatering system?

The most suitable dewatering process depends on the type and volume of the slurry to be dewatered. Belt presses were commonly used in the late 1900’s but their popularity has decreased due to innovations in screw press technology and the numerous advantages screw presses offer. Screw presses are now the most commonly used system to dewater both waste activated sludge and primary sludge. Metal sludge and construction slurries often use CakeMax® filter presses due to the very high solids concentration that can be achieved in the final cake although screw presses and belt presses have their place depending on the volumes in question. Centrifuges consume a large amount of power but can be the best if not the only solution in some applications.

The following table outlines the common benefits of screw presses, belt presses and centrifuges

How much will I need to spend on chemicals?

The rules of thumb are that approximately 4-5 kg of active polymer is required per ton of dry solids however this will vary depending on the type of sludge, the type of dewatering plant selected, and whether the sludge has been generated from a wastewater stream already using polymer. The Hydroflux team will advise based on experience or test work and can also supply chemicals via Hydroflux Utilities.

If I dewater sludge on-site, how much volume reduction can I expect to achieve?

To calculate the volume reduction, you need to know the Dry Solids (DS) concentration in the slurry to be dewatered. For example, if you currently generate 20 tons of primary sludge from a DAF system at 5% DS every day, this amounts to 1 ton of DS. If the selected dewatering plant can achieve 33.3% DS, then 1 ton of DS will generate 3 T of dewatered cake. The volume reduction is therefore 20 tons of slurry to 3 tons of cake.

Is the dewatering plant fully automated?

Dewatering equipment such as screw presses, belt presses and centrifuges are fully automated and can operate continuously. CakeMax® filter presses work on batch dewatering, but the batching can also be automated.

Does Hydroflux design and construct complete dewatering and solids handling systems?

Yes, Hydroflux will always select the most appropriate dewatering technology and design and construct all peripheral and ancillary components. This may include; slurry balancing or storage, the flocculation system or other chemical conditioning systems, sizing of the dewatering machine, the solid waste collection and offloading plant, platforms, and the control system.

Hydroflux will always select the most appropriate dewatering technology for every application

Screw press designed with duel conveying system for dewatering of waste activated sludge

Hydroflux employs qualified civil, mechanical, chemical and electrical engineers plus a team of experienced project managers, site supervisors, commissioning engineers and service technicians based in offices in most capital cities providing a local presence throughout the duration of the project.

All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Hydroflux is Australia’s first Water-tech company to achieve Climate Active certifications which means his means you are engaging with a carbon neutral organisation without increasing your carbon footprint and you are supporting positive and verified action on climate change.

Hydroflux can complete all the following works in house which are typically required to construct a wastewater treatment plant.

- Process design, development of PID’s and HAZOPS reviews

- Establishment of the most suitable wastewater treatment plant layout

- Equipment and component selection

- Civil and building designs including preparation of documentation for council or other regulators

- Electrical design and programming

- Project management and site supervision

- Environmental / Occupational health and safety plans and report

- Quality assurance plans

- Earthworks, civil works, building works, mechanical and electrical installation

- Commissioning, training and documentation as required.

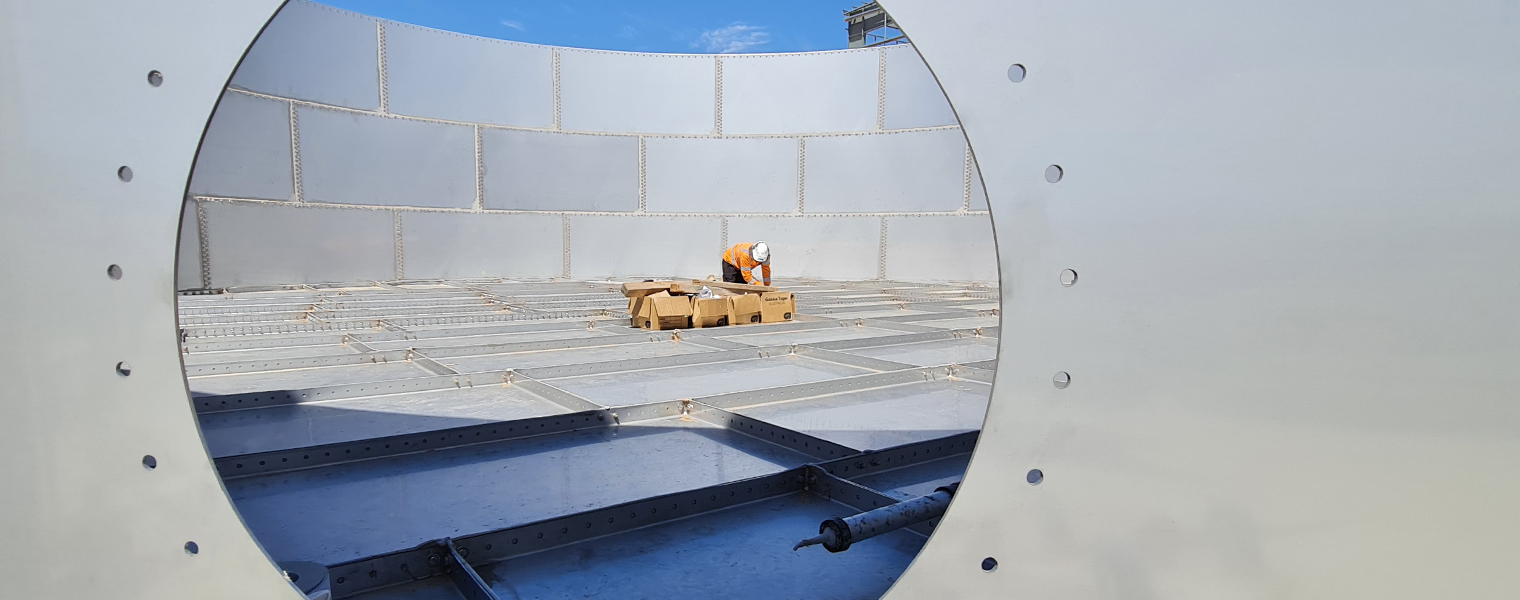

Stainless steel panel tanks are often used for aeration tanks.