Covered Anaerobic Lagoons (CAL)

Covered Anaerobic Lagoons – Efficient Wastewater Treatment with Energy Recovery

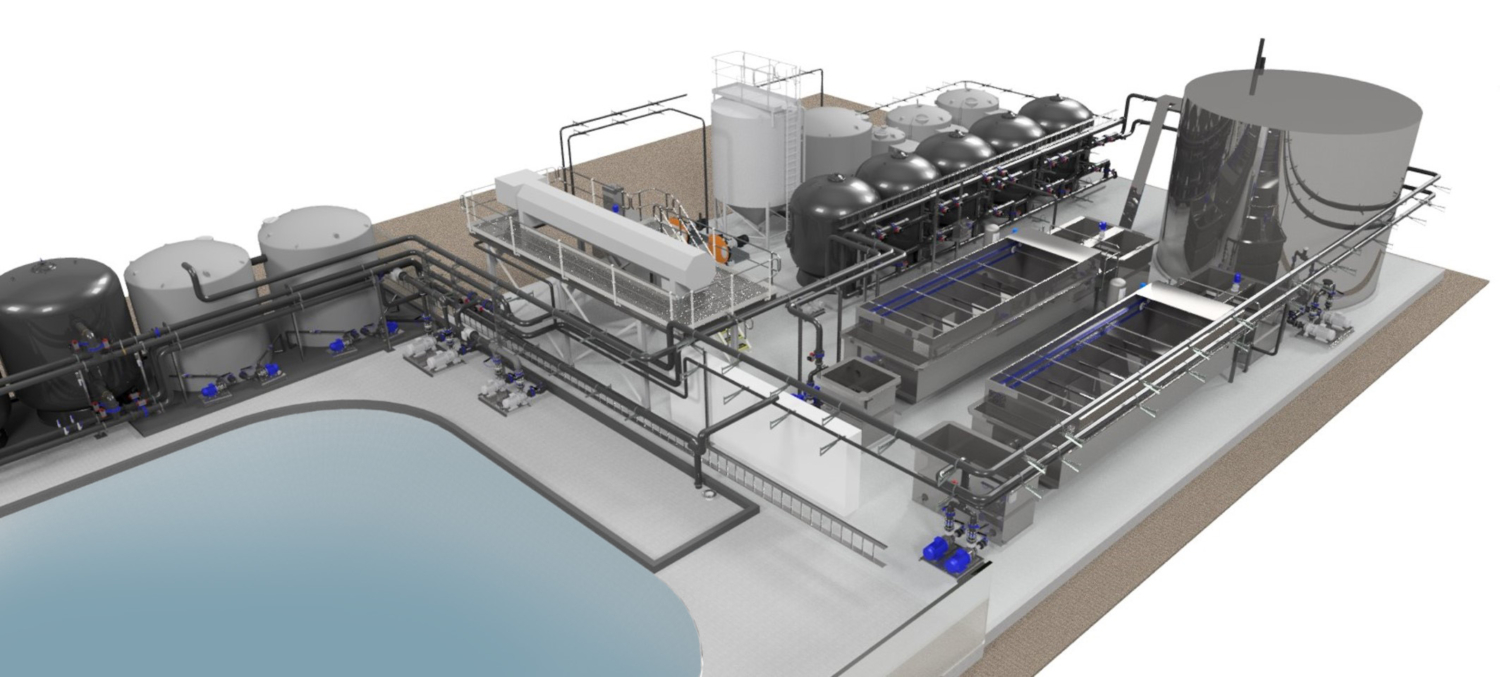

Hydroflux specialises in the design and implementation of Covered Anaerobic Lagoon (CAL) systems, offering a cost-effective and sustainable solution for treating high-strength wastewater while converting waste into valuable energy. These systems efficiently capture methane-rich biogas, which can be used for energy generation, helping industries reduce operational costs and improve environmental sustainability.

With their low operating costs, minimal odour generation, and reduced greenhouse gas emissions, Covered Anaerobic Lagoons are an ideal solution for food processing plants and other industrial facilities. They provide a reliable, low-maintenance wastewater treatment option that ensures long-term savings, making them an excellent choice for businesses looking to improve both efficiency and sustainability.

Some of the main benefits of the Covered Anaerobic Lagoon are:

- Cost-Effective Treatment – Lower capital and operational costs compared to other biological processes and removes over 80% of the COD/BOD

- Energy Recovery – Converts the majority of organics into methane-rich biogas, which can be used as a substitute for natural gas in boilers or for power generation, reducing energy costs

- Odour Control – The impermeable cover prevents foul odours from escaping, improving site conditions

- Environmental Compliance – Reduces greenhouse gas emissions

- Low Maintenance – Minimal mechanical components result in lower maintenance and operational requirements

- Sludge Reduction – Efficient digestion process minimises sludge buildup and generates far less sludge than aerobic alternatives

- Scalable & Flexible – Can be designed to handle varying wastewater loads, making it suitable for many different industries

What is Involved in Constructing a Covered Anaerobic Lagoon?

There are two aspects to consider here. Whether the lagoon is existing or a new lagoon is to be constructed.

Covering existing ponds

Retrofitting an existing anaerobic pond with a cover is a cost-effective solution for improving treatment efficiency, controlling odours, and capturing biogas for energy recovery or flaring, and reducing greenhouse emissions.

The process begins with assessing the pond’s structural integrity, ensuring the embankments are stable and the base is suitable for continued operation. Once confirmed, a floating or fixed geomembrane cover – typically made from high-density polyethylene (HDPE) or reinforced polypropylene – is installed. The cover is anchored securely around the perimeter to prevent displacement while still allowing for controlled movement in response to gas accumulation and water level changes.

To ensure effective biogas capture, a network of gas collection pipes and pressure relief valves is integrated beneath the cover. These components channel the methane-rich biogas to a centralised collection point, where it can either be flared to reduce greenhouse gas emissions or utilised as a renewable energy source.

Constructing new ponds

The first stage in constructing a CAL involves site selection and excavation, considering factors such as soil stability, groundwater levels, and proximity to wastewater sources. As the lagoon is typically designed with a retention time of approximately 20 days and a depth of up to 7 meters to enable effective breakdown of organic matter, a CAL is most suited for more rural applications.

Once excavation is complete, the pond is lined with multiple layers of impermeable materials—typically a geofabric or clay layer, followed by a high-density polyethylene (HDPE) liner to prevent seepage and groundwater contamination. Inlet, outlet, and sludge withdrawal lines are integrated into the base liner, with extraction points positioned along the outer embankment for efficient sludge removal. The CAL cover, usually made from the same HDPE material as the base liner, is anchored around the perimeter to ensure a secure seal. It is equipped with gas collection manifolds to channel biogas to an emergency flare, gas storage, or gas utilisation systems, and features overpressure relief mechanisms and storm water drainage facilities to maintain system integrity and prevent water accumulation.

Handling of Biogas

Biogas primarily consists of 60–65% methane (CH₄) and 35–40% carbon dioxide (CO₂). Additionally, it contains trace amounts of hydrogen sulfide (H₂S), nitrogen (N₂), hydrogen (H₂), and moisture. The exact composition varies depending on the type of organic waste being digested and the efficiency of the anaerobic process.

In industrial settings, biogas is most commonly used as a fuel for boilers, reducing dependence on fossil fuels. When generated in sufficient quantities, it can also be converted into electricity using gas engines or turbines, making it a viable option for energy self-sufficiency. However, before biogas can be used efficiently, it must be conditioned and treated to meet the specifications required for its intended application.

This treatment process often includes chilling to remove moisture and scrubbing to eliminate impurities like hydrogen sulfide, which is corrosive to equipment. Regardless of whether biogas is reused or not, a gas flare system is always installed to ensure any excess gas is safely burned off, preventing the uncontrolled release of methane into the atmosphere as a greenhouse gas. Proper treatment and handling of biogas are essential for ensuring safety, maximising energy recovery, preventing corrosion and minimising the environmental impact.

Hydroflux supply a range of biogas treatment systems that are engineered to maximise the recovery and utilisation including:

- Biogas Collection: Positive displacement blowers will often be required to transfer biogas from the covered anaerobic lagoon at a controlled rate and pressure to downstream equipment

- Biogas Chilling: Digester produced biogas is 100% water saturated as it cools in the lines to the point of reuse, large amounts of water will condense in the piping system . Hydroflux will incorporate the most suitable biogas cooling system into the treatment process

- Biogas Treatment: Removal of hydrogen sulphide from biogas is essential to avoid rapid corrosion. Hydroflux offer a range of chemical, media or biological gas scrubbers that will ensure that the biogas is suitably conditioned for reuse

- Biogas Storage: Biogas storage is typically achieved using double membrane gas holders, which provide a flexible and reliable solution for accommodating fluctuations in gas production. The outer membrane offering weather protection and an inner membrane adjusting to gas volume changes

FAQs

Several factors must be considered to determine whether a covered anaerobic lagoon or anaerobic digestion is a suitable wastewater treatment solution for your facility. Anaerobic treatment alone does not reduce BOD to levels suitable for direct discharge or reuse, nor does it significantly lower nutrient levels. However, for wastewater with high COD loads, anaerobic digestion upstream of an aerobic process—such as the Hydroflux SBR, MBR, or MBBR—can significantly reduce the load on the aerobic stage. This not only lowers the overall capital and operating costs of the treatment plant but also enables the capture and reuse of biogas.

Covered anaerobic lagoons typically require a retention time of up to 20 days and a depth of up to 6 meters, making them best suited for sites with sufficient land availability. If space is limited but anaerobic treatment remains a viable option, Hydroflux offers a range of high-rate anaerobic digestion systems designed for compact installations.

Anaerobic treatment is most effective for relatively high wastewater flows, and for economical biogas recovery, a minimum COD load of 3–4 tonnes per day is generally required. For this reason industries with high-strength organic wastewater benefit the most from covered anaerobic lagoons. This includes food processing (such as dairy, meat, and beverage production), agricultural industries and some other manufacturing sectors with high COD loads.

The amount of gas generated depends on a number of factors but of most value is the COD load. As a rule of thumb for every Kg of COD, 0.35 m3 of biogas will be generated. This biogas will need to be conditioned for reuse as it will be contaminated with carbon-dioxide (CO2) along with some trace gasses such as hydrogen sulphide (H2S), nitrogen (N2), hydrogen (H2) and oxygen (O2).

Yes, Hydroflux provides complete design and construction services for covered anaerobic lagoons, including process design, engineering, installation, and commissioning. Our expertise ensures a fully integrated solution that maximises efficiency, minimises costs, and optimises biogas recovery for your wastewater treatment needs.

Covered anaerobic lagoons generally have lower maintenance requirements compared to most other wastewater treatment systems, thanks to their simple, passive design. However, to ensure optimal performance and longevity, regular inspections and maintenance are essential. Key maintenance tasks include:

- Cover Inspection and Integrity – The impermeable cover is crucial for capturing biogas, and its integrity must be regularly checked for any leaks or damage. A compromised cover can lead to biogas loss and affect treatment efficiency.

- Biogas Collection and treatment System – The biogas collection system should be periodically inspected to ensure that methane is being captured and treated efficiently. Equipment such as blowers, flares, scrubbers and chillers will also require periodic maintenance.

- Sludge Management – As organic matter decomposes in the lagoon, it generates sludge, which settles at the bottom. While covered anaerobic lagoons typically generate far less sludge than other treatment systems, periodic removal of accumulated sludge is necessary to maintain proper function. The frequency of sludge removal will depend on the wastewater characteristics and the lagoon’s retention time.

- Water Quality Monitoring – Regular testing of the effluent quality is important to ensure that the lagoon is effectively reducing COD and other pollutants.

- Cover Cleaning – Over time, the cover can accumulate dirt, debris, or even algae growth, which can impede its effectiveness. Light cleaning may be necessary to maintain the proper functioning of the lagoon.

Hydroflux provides ongoing support, including scheduled maintenance, monitoring services, and emergency troubleshooting. This proactive approach helps ensure that the system continues to perform efficiently over its lifetime, minimising downtime and maintaining environmental compliance.

Choosing Hydroflux means selecting a trusted partner that combines high-quality systems, specialised equipment, and deep industry expertise to deliver outstanding wastewater treatment solutions.

Contact us for a discussion on covered anaerobic lagoons and biological treatment options for your site.

Design and Construction Capabilities

With a team of qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians, Hydroflux offers flexible contract options, ranging from equipment design and supply to full turnkey installations with expert execution at every stage. Our offices across Australia provide a strong local presence, ensuring seamless project management from design through to installation. Additionally, Hydroflux offers post-installation routine service contracts to maintain system performance and longevity.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand market and also carbon-neutral. Click here to find out what this means for you.