Dairy

Dairies: Integrated Process Water and Wastewater Treatment Solutions

Hydroflux provides comprehensive solutions for both process water and wastewater treatment for all type of dairies. Our process water treatment technologies include filtration, softening, demineralisation, and disinfection to ensure water quality meets production standards. For wastewater treatment, Hydroflux integrates Dissolved Air Flotation (DAF) for grease and solids removal, biological treatment (aerobic and anaerobic) for organic load reduction, and membrane filtration for water recovery and reuse.

By optimising both process water and wastewater treatment, Hydroflux helps dairy processors improve operational efficiency, enhance sustainability, and ensure compliance.

View the photo gallery below for examples of treatment plants Hydroflux has constructed for the Dairy industry

Scroll down the page or click on the links to go directly to Process Water Solutions, our Design and Construct capabilities or our Support Services

Tailored Wastewater Treatment Designs for Diverse Dairy Applications

Hydroflux evaluates each project individually, considering performance requirements, CAPEX, and OPEX to ensure the most efficient and cost-effective solution. We assess wastewater characteristics, discharge regulations, space constraints, and operational sustainability to optimise system design.

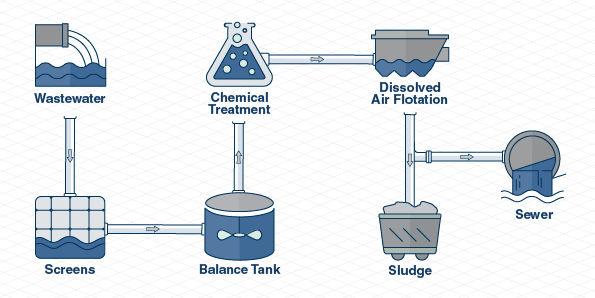

Trade Waste Discharge

For urban dairy processing facilities discharging wastewater to the sewer as trade waste, Hydroflux typically provides an automated rotary screening system followed by a HyDAF unit which will generally ensure compliance for trade waste discharge.

The diagram illustrates a typical wastewater treatment process for urban sites discharging to a local sewage treatment plant. We primarily use process equipment, including the HyDAF Dissolved Air Flotation system from our proprietary range, and offer complete turnkey design and construction solutions.

Each wastewater treatment system is designed with a tailored chemical treatment program to achieve the required level of treatment, which may include pH control, coagulation, and flocculation, either individually or in combination. With increasing regulations and the rising cost of sludge disposal, Hydroflux will often also incorporate sludge dewatering into the overall process.

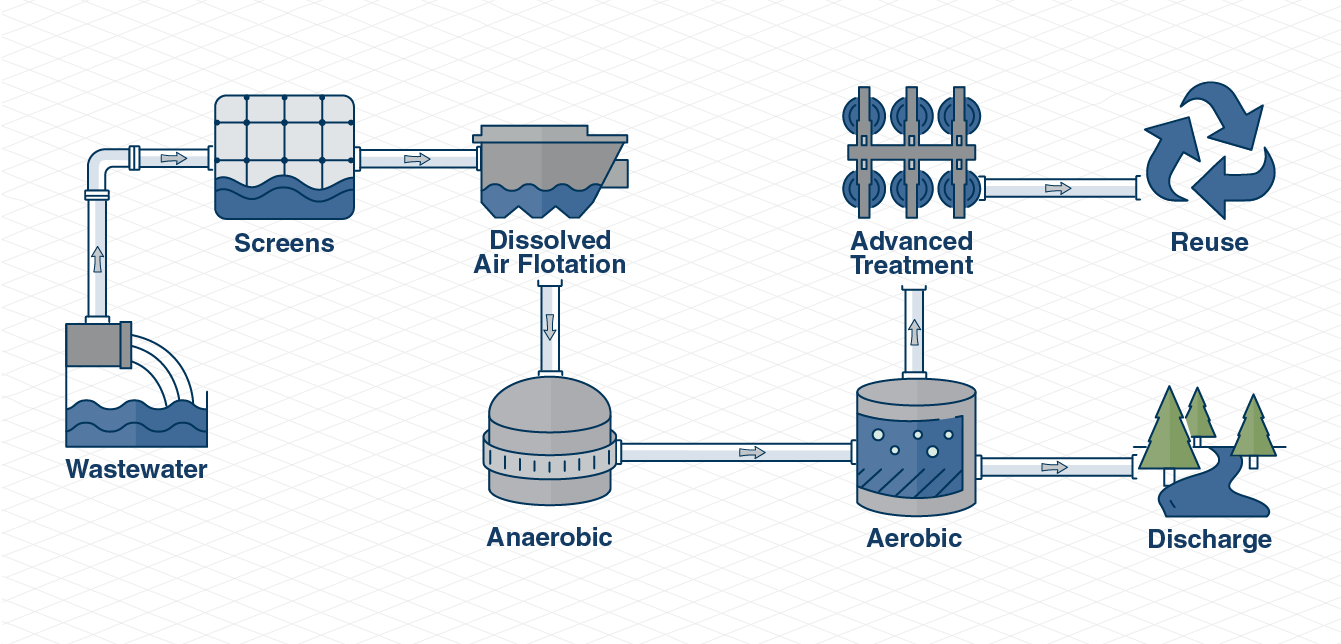

Irrigation or Environmental Discharge

For dairies located in rural areas where wastewater is discharged to the environment via irrigation or to rivers and streams under EPA licences, a wastewater treatment plant incorporating a biological process is essential for the removal of organics and nutrients.

After pre-treatment, which typically includes screening and a Dissolved Air Flotation (DAF) system for solids and grease removal, wastewater is directed to an aerobic process such as a Membrane Bioreactor (MBR), Sequencing Batch Reactor (SBR), or Activated Sludge system—all of which can be designed and constructed by Hydroflux. Where suitable, anaerobic ponds can be installed upstream of the aerobic system to reduce the organic load while generating sustainable biogas. If required, additional tertiary treatment, such as filtration or disinfection, is incorporated to ensure compliance with environmental discharge standards.

Robust and Proprietary Wastewater Treatment Systems for Dairies

Dissolved Air flotation

Dissolved air flotation (DAF) is the most commonly used wastewater treatment method for dairies, offering efficient removal of suspended solids, oils, and greases. Hydroflux provides a comprehensive range of HyDAF systems tailored to suit any food processing application. Every Hydroflux DAF system is precisely sized using a proven in-house engineering tool, ensuring optimal performance based on flow rates and solids loading.

Hydroflux’s comprehensive range of dissolved air flotation units ranges from 10 kL/hr to over 300 kL/hr as standalone units and can be configured with several options for automated settled sludge removal to further streamline operation and maintenance.

Biological processes

Hydroflux designs tailored biological treatment solutions based on treatment objectives, discharge requirements and available space. Our portfolio includes:

- Sequencing Batch Reactors (SBR)

- Membrane Bioreactors (MBR)

- Moving Bed Biofilm Reactors (MBBR)

- Conventional activated sludge processes (tank or pond-based)

For high-strength wastewater with elevated COD levels, Hydroflux can design and construct High-rate anaerobic reactors or covered anaerobic ponds which provide a cost-effective and sustainable solution by offering energy recovery.

With expertise in all aerobic and anaerobic biological treatment processes, Hydroflux designs each system based on performance requirements, regulatory compliance, and available space, ensuring the most efficient and cost-effective solution.

Sludge Dewatering

Sludge dewatering is a critical aspect of a wastewater treatment plant to handle both primary sludge and secondary waste activated sludge (WAS) and Hydroflux carefully evaluates sludge handling as a separate process to determine the most viable solution. Hydroflux selects the most suitable dewatering technology from its extensive product range which includes:

- Screw Presses – Preferred for their energy efficiency, minimal maintenance, and high dry solids output

- Centrifuges – Effective for high-volume sludge processing and 3 phase separation abilities

- Belt Presses – Suitable for high volume continuous sludge dewatering operations

Each dewatering solution is designed to optimise sludge management, reduce disposal costs, and enhance overall wastewater treatment efficiency.

Tailored Process Water Treatment Solutions for the Dairy Industry

Hydroflux provides tailored process water treatment systems that meet the strict hygiene, quality, and regulatory standards required for dairies. With extensive experience across all food and beverage sectors, Hydroflux ensures that processors have access to high-quality, reliable, and sustainable process water to support their operations.

Hydroflux provides a comprehensive range of hygienic and non-hygienic process water treatment solutions designed to meet the specific needs of food manufacturers, including:

- Multimedia Filtration (MMF) – Removes suspended solids and particulates.

- Granular Activated Carbon (GAC) Filtration – Eliminates organic compounds, chlorine, and taste/odour issues.

- Ion Exchange Systems – Softens water by removing hardness-causing minerals.

- Ultra Filtration (UF) – Utilises hollow fibre membranes to remove suspended and colloidal solids

- NX Nano Filtration (NF) – Employs advanced crossflow NX membranes to eliminate suspended solids and targeted dissolved contaminants.

- Reverse Osmosis (RO) – A high-pressure filtration process that removes dissolved contaminants, including salts, organic compounds, and other dissolved impurities

With a comprehensive range of advanced treatment technologies, Hydroflux ensures that dairy processors have access to high-quality, compliant, and sustainable process water, optimising production efficiency and supporting long-term operational success.

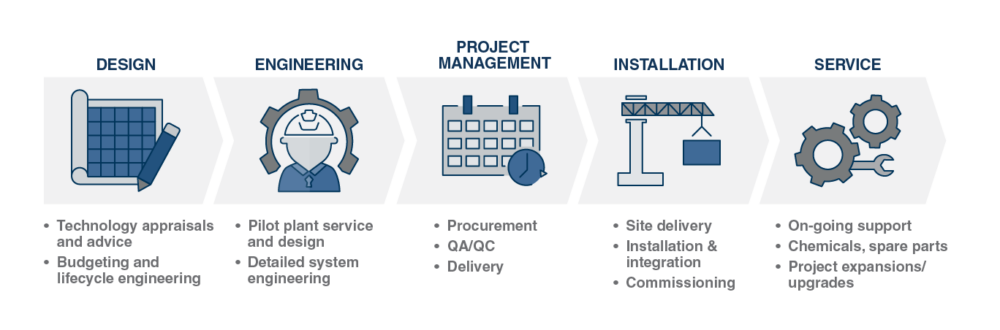

Comprehensive Design and Construct Services

Hydroflux provides comprehensive design, construction, and support services for dairies needing new, or upgraded process water and wastewater treatment plant or simply require operational expertise.

Our turnkey solutions cover everything from custom system design and equipment selection to full-scale construction, installation, and commissioning. We offer ongoing support, including preventative maintenance programs, operator training, chemical optimisation, and 24/7 technical assistance. With remote monitoring through HyCONNECT™, we provide real-time diagnostics and troubleshooting, ensuring long-term performance, minimal downtime, and cost-effective operation for every plant.

End-to-End Wastewater Treatment Solutions with Expert Project Execution

With a team of qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians, Hydroflux offers flexible contract options, ranging from equipment design and supply to full turnkey installations with expert execution at every stage. All projects are conducted under externally approved occupational health and safety, and environmental management systems.

Our offices across Australia provide a strong local presence, ensuring seamless project management from design through to installation. Additionally, Hydroflux offers post-installation routine service contracts to maintain system performance and longevity.

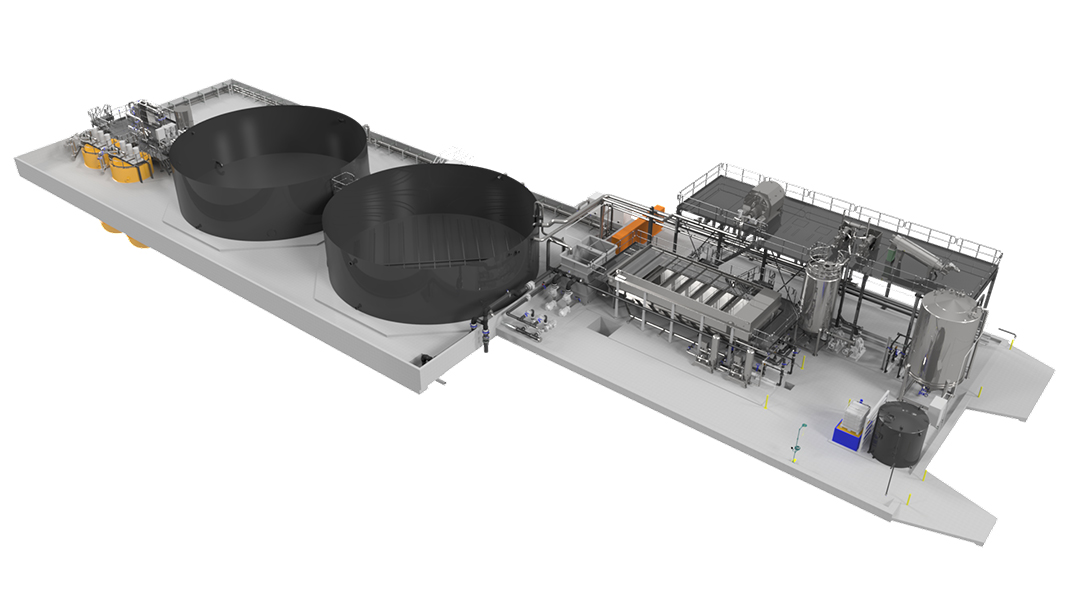

Below is a 3D drawing of a treatment plant recently constructed for a food processing plant in SA comprising primary screening, balancing, a HyDAF dissolved air flotation system and sludge dewatering.

Comprehensive Support for Dairy Water & Wastewater Treatment Plants

Hydroflux is a trusted partner for the food processing industry, providing end-to-end water and wastewater treatment solutions. Beyond system design and installation, Hydroflux offers chemical optimisation, preventative maintenance, biological plant modelling, and remote monitoring, ensuring long-term reliability and performance for every plant.

Chemical Optimisation

Hydroflux offers a comprehensive range of proprietary chemicals, including coagulants, antiscalants, acids/alkalis, oxidising/reducing agents, and proprietary cleaning and sanitising products. These chemicals are formulated to optimise process water feed conditioning before and after treatment, or enhancing the performance of your wastewater treatment plant. Our chemists work closely with the project delivery team to develop a site-specific chemical program that ensures maximum treatment efficiency and cost-effectiveness.

Preventative Maintenance & Service

To guarantee consistent performance from day one, Hydroflux provides customised service and maintenance programs. Our engineers and technicians discuss preventative maintenance strategies during the construction phase, offering routine service, periodic overhauls, and full plant operation support. Our service team is available 24/7 to respond to unforeseen breakdowns, ensuring uninterrupted plant operation.

Remote Monitoring

All Hydroflux process water treatment plants come equipped with our proprietary HyCONNECT™ remote monitoring system, providing instant online technical support and troubleshooting. For remote locations with limited connectivity, we offer specialty monitoring solutions to ensure continuous system oversight. No matter where your facility is located, Hydroflux specialists are just a call away, ready to assist with real-time diagnostics and performance optimisation.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand market and is also carbon-neutral. Click here to find out what this means for you.