Waste To Energy Plants

Turning Organic Waste into Renewable Energy

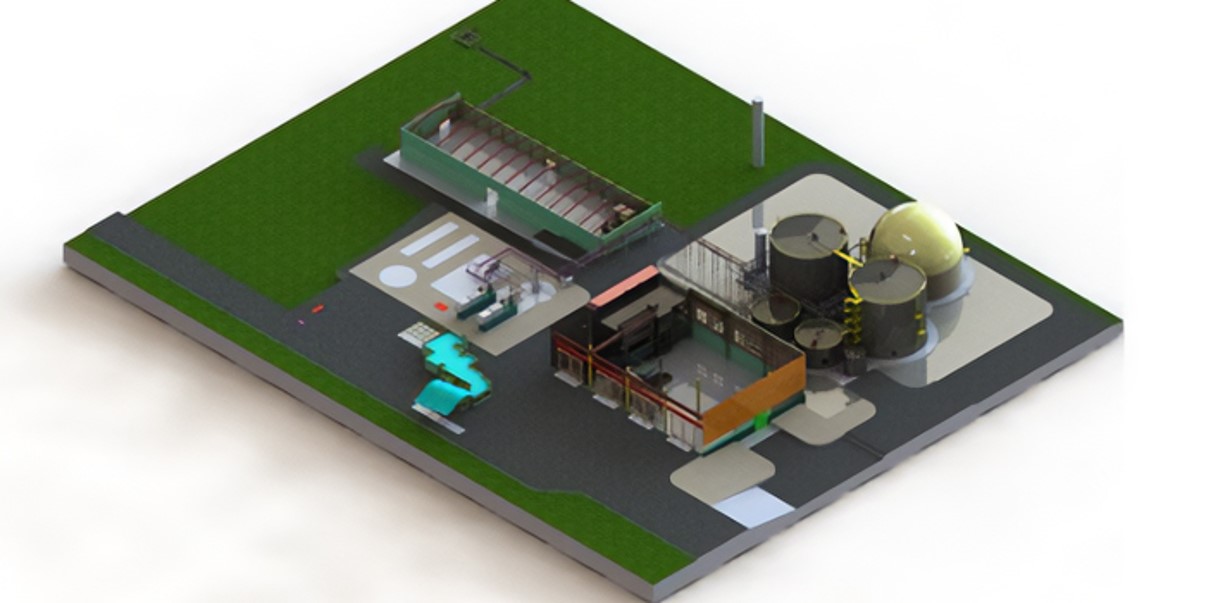

At Hydroflux, we believe that waste should be seen as an opportunity – not a burden. Our Waste-to-Energy solutions are designed to help businesses reduce waste disposal costs, lower carbon emissions, and generate sustainable energy. By harnessing advanced anaerobic digestion and biogas recovery technologies, we enable industries to convert organic waste into methane-rich biogas, which can be used for electricity generation, heat production, or even upgraded to biomethane for grid injection.

Hydroflux & AAT Biogas: A Global Partnership for Sustainable Energy

To deliver the most efficient and reliable waste-to-energy solutions, Hydroflux has partnered with AAT Biogas, a world leader in anaerobic digestion with over 30 years of experience and more than 100 biogas plants operating globally. AAT’s expertise in handling over 150 different organic substrates – including industrial waste, agricultural residues, municipal sludge, and food waste – ensures that our solutions are tailored to the diverse waste streams found in Australia, New Zealand, and the Pacific region.

By combining Hydroflux’s engineering skills with AAT Biogas’ cutting-edge reactor technology, we offer clients a seamless approach to waste-to-energy conversion – helping businesses transition to a circular economy while achieving energy self-sufficiency.

How our Waste-to-Energy Solutions Work

- Waste Collection & Pre-Treatment

Organic waste, including food waste, industrial wastewater sludge, and agricultural byproducts, is collected and prepared for anaerobic digestion. Depending on the waste type, screening, dewatering, or pre-hydrolysis may be applied to enhance digestion efficiency. - Anaerobic Digestion Process

In the absence of oxygen, microbial communities break down the organic matter within a high-performance digester. This process converts organic carbon into biogas, which consists primarily of methane (CH₄) and carbon dioxide (CO₂). - Biogas Recovery & Utilisation

The methane-rich biogas can be used for:- Electricity & Heat Generation – Via combined heat and power (CHP) systems

- Industrial Process Energy – Powering boilers and industrial operations

- Grid Injection – Upgraded biomethane can replace natural gas in national grids

- Vehicle Fuel (Bio-CNG/LNG) – A sustainable fuel alternative for transport fleets

- Digestate Management & Resource Recovery

The residual byproduct, called digestate, is a nutrient-rich material that can be used as fertiliser for agriculture, treated as a wastewater stream, or further processed into biosolids for soil conditioning—completing the circular economy loop.

Key Benefits of Hydroflux Waste-to-Energy Solutions

Cost Savings & Revenue Generation

- Lower waste disposal costs by reducing landfill volumes

- Generate energy on-site, cutting reliance on fossil fuels

- Monetise biogas by selling excess power back to the grid

Environmental & Sustainability Advantages

- Reduce carbon footprint and achieve net-zero targets

- Decrease methane emissions from uncontrolled waste decomposition

- Improve wastewater management by efficiently treating organic-rich effluents

Cutting-Edge Technology & Expertise

- Industry-leading anaerobic digesters with hydraulic mixing technology (no moving parts, reducing maintenance)

- Custom-engineered solutions for food processing, beverage production, municipal waste treatment, and more

- Comprehensive project support from feasibility studies to full-scale implementation

Industries We Serve

Our waste-to-energy solutions are ideal for a wide range of sectors, including:

- Food & Beverage Processing (dairy, breweries, meat processing, sugar mills)

- Agriculture & Livestock (manure, crop residues, food waste)

- Municipal Waste Management (organic household waste, sludge from wastewater plants)

- Industrial & Manufacturing (paper mills, chemical processing, bio-based industries)

By leveraging anaerobic digestion and biogas recovery, businesses can turn organic waste into an asset—supporting energy independence, sustainability goals, and operational efficiency.

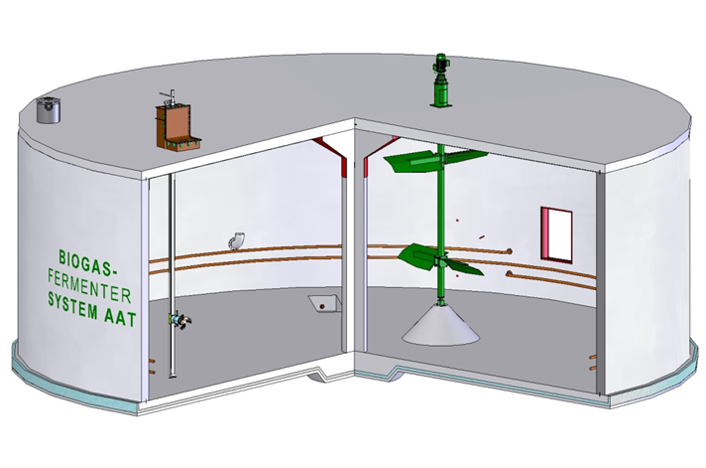

Types of Digester

Different substrates require different digester technology.

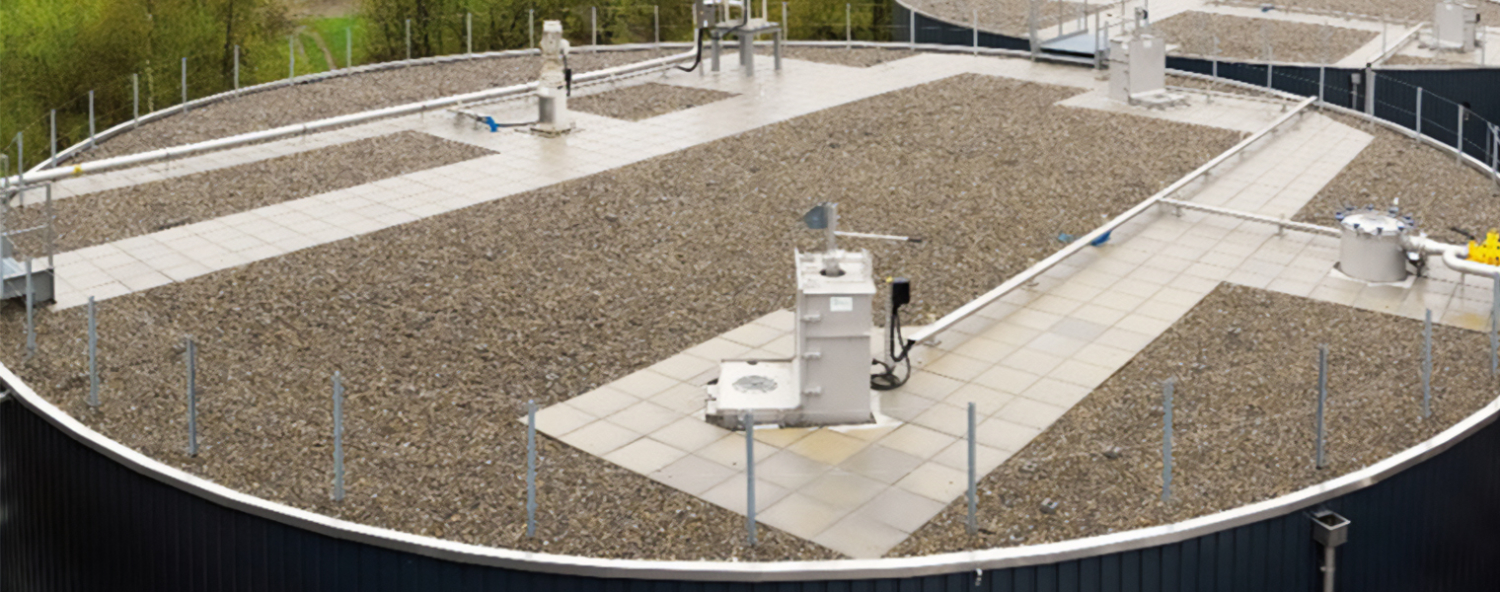

AAT Biogas offers a range of advanced anaerobic digesters, each tailored for specific waste streams to maximise biogas production and energy recovery. Their Flat (Low Profile) Digester is used for buffering and hydrolysis, particularly in agricultural waste treatment. The Hydraulic Digester (without mechanical mixer) and CSTR Digester with central agitator are ideal for high-solids applications like sewage sludge, food waste, and industrial wastewater, with the latter featuring continuous mixing for enhanced efficiency.

The MSB Digester is specialised for whey plants and wastewater with high suspended solids and fat content, while the UASB Digester is a high-rate system designed for low-solids, high-strength wastewater from industries such as breweries, dairy, and paper production. Together, these technologies allow Hydroflux and AAT Biogas to deliver customised waste-to-energy solutions, helping businesses reduce waste, generate renewable energy, and achieve sustainability goals.

| Digester Type | Common Use |

| Flat (Low profile) Digester | 1st stage digesters for buffering and hydrolysing AD of agricultural waste and plants AD with integrated gas storage |

| Hydraulic Digester (without mechanical mixer) | Sewage plants, food waste, sludges from industrial water treatment and other high solids applications |

| CSTR Digester with central agitator | Sewage plants, food waste, sludges from industrial water treatment and other high solids applications |

| MSB Digester | Whey plants and wastewater with high fractions of suspended matter and also high fat contents |

| UASB Digester | High strength wastewater with the low solids content in applications such as breweries, beverage, dairy and paper |

This diagram is an example of a flat low profile digester which is just one of the many Hydroflux can provide. Some of the key features of this arrangement include:

- Digester dimensions: low height / diameter ratio

- Construction: steel reinforces concrete floor, walls and ceilings with center column

- Agitation: vertical shaft mixer combined with submersible mixer

- Feeding system: dry material feeder

- Heating: heating coils inside digester

- Desulphurisation: integrated in digester or external biological desulphurisation

Our Typical Services Include:

- Plant concept design and equipment selection

- Process Design

- Mechanical and Electrical design

- Control systems design

- Civil design and formwork drawings

- Piping drawings

- Tank structural analysis

- Tender and procurement

- Construction supervision

- Commissioning and operator training

Why Choose Hydroflux?

With decades of experience in wastewater treatment and biogas technology, Hydroflux is uniquely positioned to deliver turnkey waste-to-energy solutions that maximise efficiency, minimise costs, and provide long-term reliability. Our partnership with AAT Biogas ensures that our clients receive proven European technology tailored to the needs of Australia, New Zealand, and the Pacific region.

Proven Track Record – 100+ AAT biogas plants installed globally.

End-to-End Expertise – From design to commissioning & ongoing support.

Sustainable Innovation – Helping businesses meet environmental targets.

Choosing Hydroflux means selecting a trusted partner that combines high-quality systems, specialised equipment, and deep industry expertise to deliver outstanding wastewater treatment solutions.

Contact us for a discussion on covered anaerobic lagoons and biological treatment options for your site.

Design and Construction Capabilities

With a team of qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians, Hydroflux offers flexible contract options, ranging from equipment design and supply to full turnkey installations with expert execution at every stage. Our offices across Australia provide a strong local presence, ensuring seamless project management from design through to installation. Additionally, Hydroflux offers post-installation routine service contracts to maintain system performance and longevity.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand market but also carbon-neutral. Click here to find out what this means for you.