Reinforcing Our Position in The Green Energy Space

October 26, 2022

Hydroflux has been awarded a tender to supply a pilot scale high-grade ultrapure water treatment system for Graphite Energy’s groundbreaking Green Steam™ project.

Over the past 24 months, the world has seen unprecedented levels of investment into decarbonizing global industrial processes. The food and beverage sector is no different, as manufacturers of all sizes are pledging to make net zero targets, with most matching or exceeding 2050 deadlines.

One of the major challenges for the F&B sector has been a reliable and efficient method of generating renewable thermal energy at high enough temperatures to meet the steam demands. Food and beverage manufacturers are often operating 24 hours per day and readily available steam is critical to how they operate.

Currently, most steam in the F&B sector is produced by natural gas boilers as supply is reliable and combustion provides a direct route for energy transfer into steam. Converting the variable capacity of renewable energy production from solar and wind into high-temperature, high-grade heat sources is the key challenge to reducing reliance on natural gas and decarbonising F&B manufacturing.

One company making strong headway in this battle is Australian firm Graphite Energy. Graphite Energy are pioneering the concept of thermal storage and Green Steam™ production in Australia. Their graphite thermal energy storage (TES) system offers a low cost, reliable and readily scalable solution for converting renewable energy directly into steam. The TES system is capable of continued steam production for long periods of time after the supply of renewable electricity is no longer available.

One major advantage of the Graphite Energy TES system is the modular design of the storage system. This concept allows it to be easily scaled up or down and makes the solution particularly attractive for F&B manufacturers of all shapes and sizes.

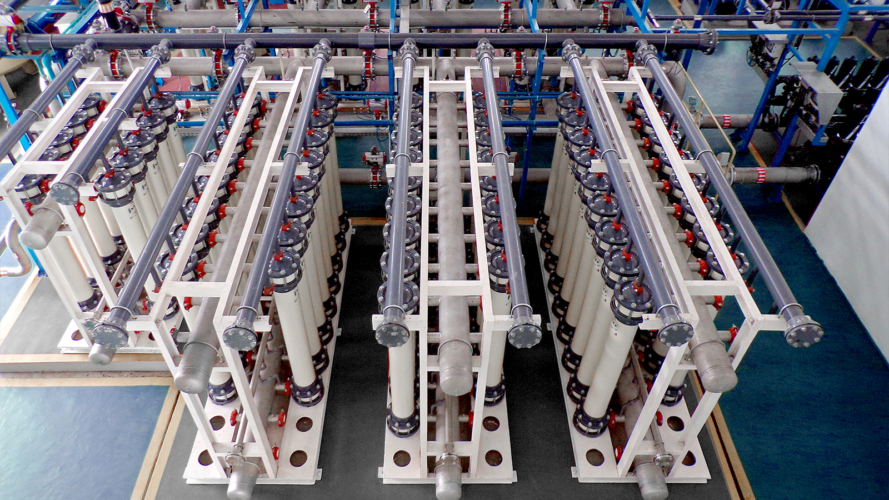

Graphite energy are currently developing a pilot project for a major F&B client in Wodonga Victoria. This project follows on from successful test work at their Lake Cargelligo site. Hydroflux are playing a small but critical role in the development of the Wodonga pilot plant through the supply of a specially designed ultrapure water (UPW) system. The Hydroflux HyPURE® UPW process utilises several treatment stages including ion exchange, reverse osmosis, membrane degassing and finally electrodeionization. The plant is fully automated and accessible remotely to minimize site maintenance time.

Tyreen Hasna, Hydroflux project manager has been working since the early engagement with Graphite Energy, ensuring energy and water efficiency were central to the design. “Hydroflux has developed specific design features to reduce both energy and water usage on the water treatment system and TES, while still being able to meet peak water usage demands.”

“We talk a lot about reducing our carbon emissions, especially here at Hydroflux, while we’ve become pretty good at it (we are a carbon-neutral certified company group!), we’re very excited to be working with Graphite Energy on a project which has the potential to change the way Australia produces and uses energy.”

Tyreen Hasna, Hydroflux project manager

“The F&B industry is an important place to start, as it uses 30% of the available energy globally and contributes to approximately 20% of the world’s greenhouse gas emissions. The displacement of fossil fuel usage can have a drastic impact on global efforts to reach net zero.”

The project further reinforces Hydroflux position as a leader in the green energy space through our drive to provide innovative, energy-saving solutions in the biogas, green hydrogen and green steam sectors. Hydroflux are looking forward to successful commissioning the UPW plant alongside Graphite Energy in the very near future.

“Hydroflux have been instrumental in improving the overall energy efficiency of the water treatment and associated systems. Their engineering expertise and flexibility have facilitated the integration process with the TES.” Says Casey Walsh, Head of Engineering at Graphite Energy

For more information on Green Energy please Click Here.

About Hydroflux

The Hydroflux Group consist of eleven specialist companies which aim to deliver the highest level of engineering and scientific knowhow to the emerging issues of sustainability, climate adaptation and environmental protection with a specific focus on water and wastewater.

The Group employs over 100 staff and operates throughout Australia, New Zealand and the Pacific Islands with office locations in Sydney, Melbourne, Brisbane, Perth, Auckland, Suva and Portsmouth

Up Next

HyPURE® NX ZeroBrine Nanofiltration Process for PFAS Removal

Hydroflux signs Channel Partnership Agreement with NX Filtration

Categories

- Tradeshows

- Climate

- Community Engagement

- Corporate Announcements

- Group News

- Newsletters

- Product News

- Project Announcement