Construction Water

Construction Water Treatment for Major Infrastructure Projects

Hydroflux provides specialised construction water treatment solutions for major infrastructure projects, ensuring effective solids management and compliance with the most stringent environmental and regulatory standards.

For temporary construction site operations, we offer modular and scalable systems designed for quick deployment and adaptability to evolving site conditions. For long-term infrastructure projects, we deliver advanced, custom-engineered systems that are durable, reliable, and built for sustained performance throughout the project lifecycle. We also provide potable water and wastewater treatment systems for remote locations.

Hydroflux’s Proven Track Record in Water Treatment for Tunnelling and Construction

Our team has extensive expertise in water treatment and a deep understanding of the unique challenges in tunnelling and construction projects. This expertise has allowed us to design, build, and support many high-performance treatment plants across Australia, contributing to some of the country’s most significant infrastructure projects.

Explore the photo gallery below to see examples of temporary and permanent water treatment systems designed and constructed by Hydroflux.

Each site presents different conditions, so we focus on designing customised solutions that ensure compliance, efficiency, and sustainability.

Comprehensive Water Treatment Solutions for Tunnelling and Construction

Over the past decades, discharge requirements for water treatment plants in tunnelling and construction have become increasingly stringent due to tighter environmental regulations.

We design systems tailored to the specific contaminants and discharge requirements of each project, working closely with our clients to implement a comprehensive risk management approach. Our systems are engineered to effectively treat a wide range of contaminants, including suspended solids, turbidity, pH fluctuations, heavy metals, oils, PFAS, and nutrients, ensuring full compliance with regulatory standards.

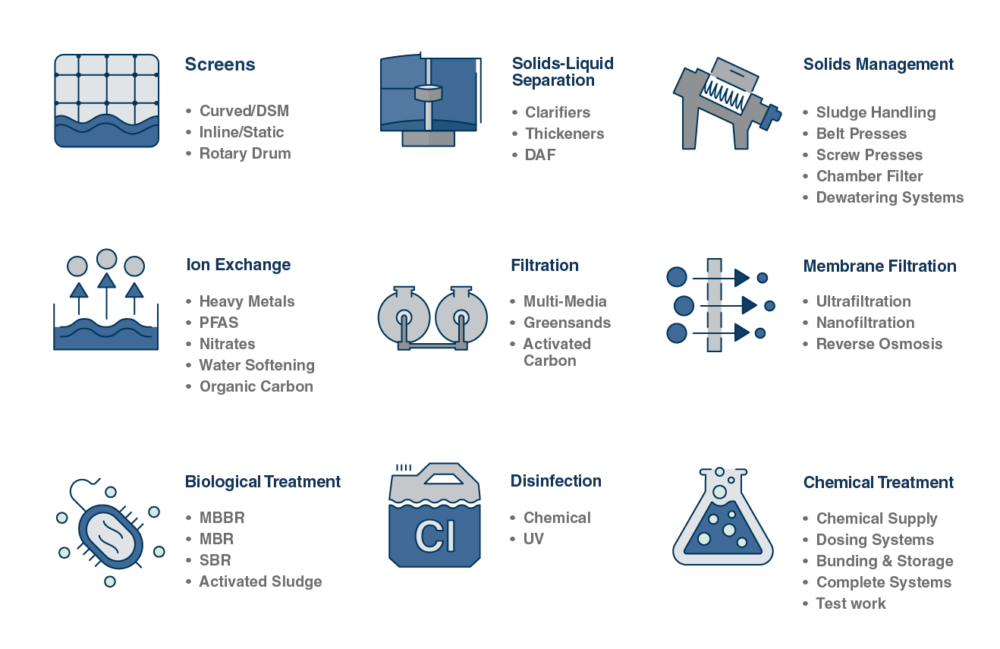

Some of our key processes and technologies include:

Hydroflux is Australia’s leading water treatment company, committed to supporting the construction industry with innovative water and wastewater treatment solutions.

Temporary Water Treatment Plants

Our modular and containerised treatment systems are designed for rapid deployment and easy relocation, providing a cost-effective and flexible solution for managing wastewater on construction sites. These systems typically include sedimentation tanks, clarifiers, chemical treatment, and sludge handling facilities, with additional filtration and adsorption processes incorporated as needed.

We have designed and constructed systems to handle up to 50 L/s in a single train with flexible configurations to adapt to varying site conditions and treatment needs, incorporating:

- Screens for removing large debris, such as rocks and stones

- Conical-bottomed storage tanks for gross solids sedimentation and flow balancing

- High-performance clarifiers for efficient solids separation

- Chemical dosing systems compliant with AS 3780, AS 1940, and AS/NZS 4452

- Dewatering systems, including belt presses, filter presses, and screw presses in a TunnelMax configuration

- Multimedia filtration for fine solids removal

- Greensand filtration targeting metal removal, including iron and manganese

- Activated carbon filtration for adsorption of organic pollutants

- Ion exchange systems using specialised resins to target PFAS, nutrients, and heavy metals

- Membrane filtration technologies, including Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO), for advanced water treatment

- Automated control and monitoring systems for real-time performance optimisation and compliance tracking

Rapid Deployment and Easy Relocation

Hydroflux’s temporary wastewater treatment systems are engineered for rapid mobilisation and easy transport, making them ideal for short-term and dynamic project needs. With our extensive track record and the large number of systems we have installed, we can often integrate high-quality used equipment, reducing lead times and enabling faster, more cost-effective installations without compromising performance or reliability.

Permanent Water Treatment facilities

Once an infrastructure project is towards completion, we provide advanced, custom-engineered water treatment systems to handle ground water and runoff. We work closely with our clients throughout the entire project lifecycle, from initial concept development to commissioning and ongoing support.

Our engineered solutions offer robust performance, optimised treatment processes, and adaptability to future project expansions or regulatory changes.

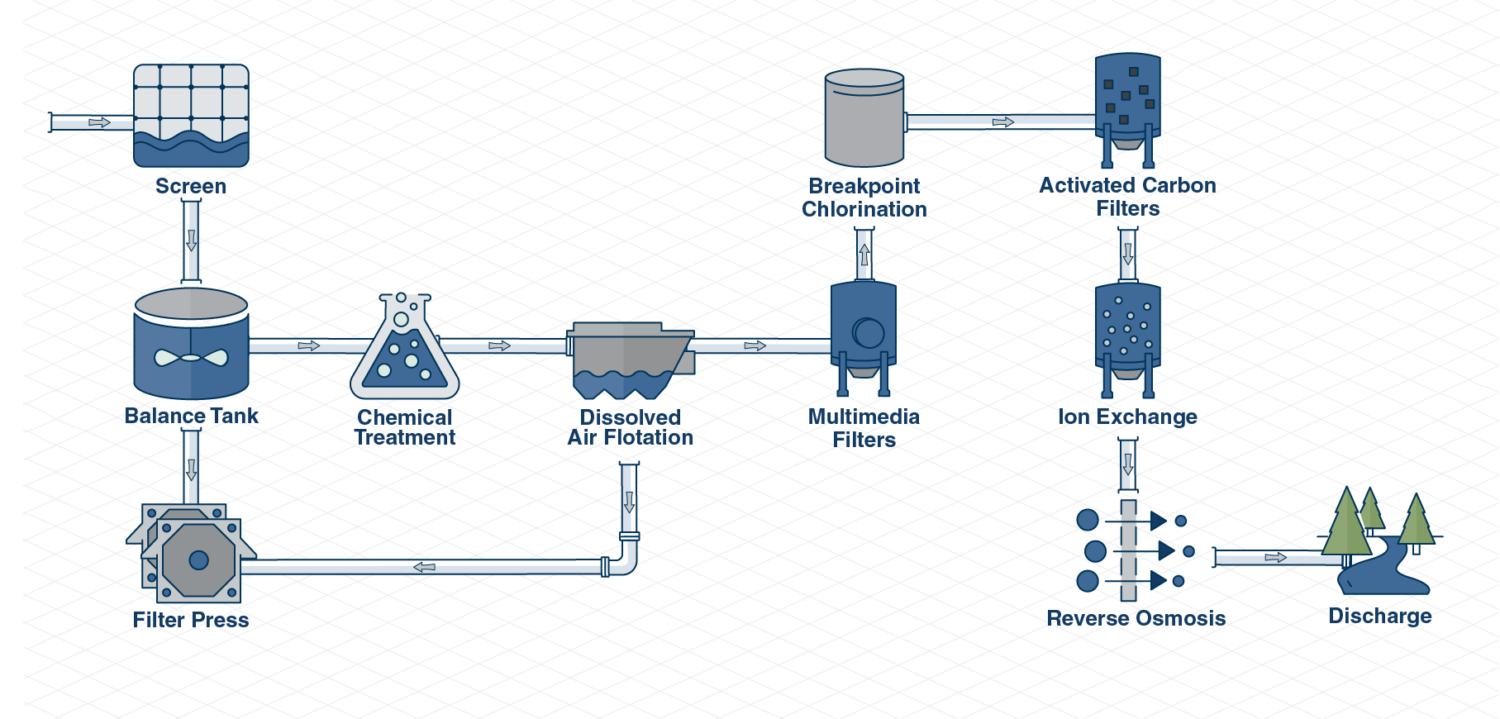

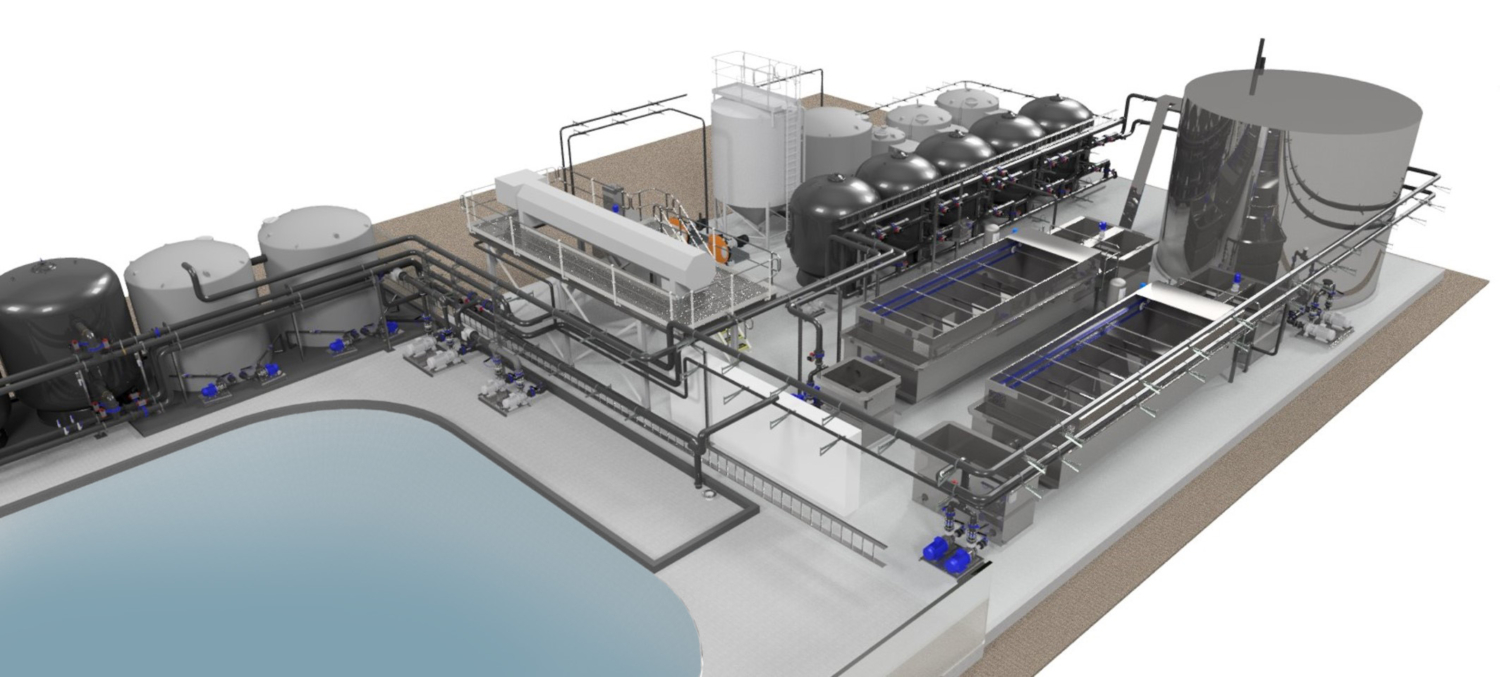

The animation below shows a water treatment plant that Hydroflux designed and constructed for a tunneling project in Sydney to treat water following completion. The treatment plant comprises balancing, dissolved air flotation, various filtration systems and sludge dewatering. The process diagram is a typical concept.

Common Elements of a Permanent Water Treatment Plant

We have designed and constructed systems to handle up to 30 L/s in a single train with Flexible configurations to adapt to varying site conditions and treatment needs incorporating:

- Screens for removing large debris, such as rocks and stones

- Conical-bottomed storage tanks for gross solids sedimentation and flow balancing

- High-performance clarification for efficient solids separation using settlement typically via lamella clarifiers or via dissolved air flotation

- Chemical dosing systems compliant with AS 3780, AS 1940, and AS/NZS 4452

- Dewatering systems, including belt presses, filter presses, and screw presses

- Multimedia filtration for fine solids removal

- Greensand filtration targeting metal removal, including iron and manganese

- Activated carbon filtration for adsorption of organic pollutants

- Ion exchange systems using specialised resins to target PFAS, nutrients, and heavy metals

- Membrane filtration technologies, including Ultrafiltration (UF), Nanofiltration (NF), and Reverse Osmosis (RO), for advanced water treatment

- Automated control and monitoring systems for real-time performance optimisation and compliance tracking

Fully Customised, On-Site Potable Water Treatment

Potable water is one of the most critical resources on remote sites, supplying drinking water, site amenities, safety equipment, and essential process systems. Hydroflux provides fully customised, on-site potable water treatment solutions tailored to the specific water source and site requirements.

Groundwater is a common source for potable water treatment, but its quality varies depending on location and geological conditions. In some areas, high levels of dissolved minerals and salts can result in brackish water, requiring specialised treatment. Hydroflux designs and implements tailored treatment processes to ensure safe, high-quality potable water, typically incorporating the following process elements.

Depending on your water source:

High Turbidity – The initial stage of treatment will usually involve chemical coagulation followed by clarification. This process aims to remove suspended solids and particles from the water, enhancing its clarity and reducing turbidity.

Non-Brackish Water – With low levels of dissolved salts, the secondary and final treatment approach involves media filtration followed by disinfection. Media filtration effectively removes impurities and particulate matter from the water, while disinfection destroys harmful microorganisms, ensuring the production of potable water.

Brackish Water – A popular method of treatment is the utilisation of reverse osmosis (RO). This involves passing the brackish water through a semipermeable membrane to effectively remove dissolved solids and salts. Reverse osmosis is highly efficient, capable of removing up to 99% of salts and minerals present in brackish water. Hydroflux can also incorporate Ion Exchange technology for similar purposes, utilising a resin bed that facilitates the exchange of ions.

To simplify installation and operations, Hydroflux provides containerised and skid-mounted solutions. These compact, pre-engineered systems are designed for rapid deployment, making them ideal for remote locations with limited infrastructure. Their modular design allows for easy transportation and minimal on-site assembly

For more information on our potable water treatment solutions or to discuss your specific requirements, please contact us

Decades of Expertise in Sewage Treatment

Wastewater treatment for onsite facilities and camps must be efficient, adaptable to fluctuating water supplies and varying contaminants, and designed to support ecological restoration and monitoring, and in many operations, treated effluent is also required for reuse in onsite amenities. With over 60 years of experience, Hydroflux has been at the forefront of designing, developing, and supplying advanced wastewater treatment plants. The Hydroflux RoadTrain activated sludge plant is a highly robust and easy-to-operate system, specifically engineered for remote operations.

Its customisable design allows it to meet diverse capacity requirements, site conditions, and local water supply variations, ensuring reliable and efficient wastewater management even in the most challenging environments.

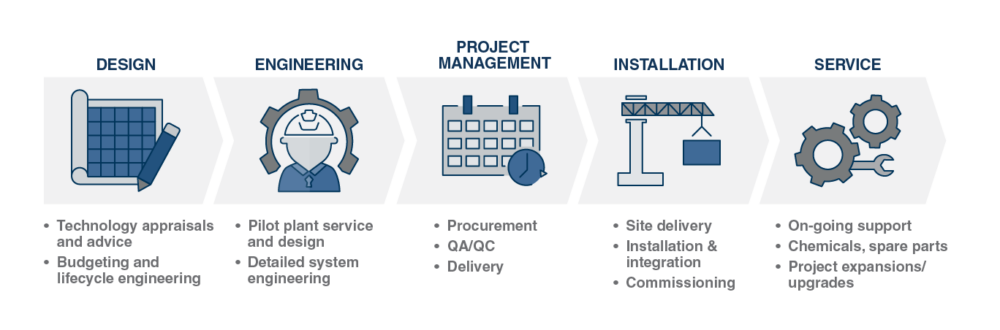

Design, Construct and Support Services

Hydroflux provides comprehensive design, construction, and support services for manufacturing facilities needing new or upgraded process water and wastewater treatment plants or simply require operational expertise.

Our turnkey solutions cover everything from custom system design and equipment selection to full-scale construction, installation, and commissioning. We offer ongoing support, including preventative maintenance programs, operator training, chemical optimisation, and 24/7 technical assistance. With remote monitoring through HyCONNECT™, we provide real-time diagnostics and troubleshooting, ensuring long-term performance, minimal downtime, and cost-effective operation for every plant.

Comprehensive Engineering and Project Execution

With a team of qualified civil, mechanical, chemical, and electrical engineers, as well as experienced project managers, site supervisors, commissioning engineers, and service technicians, Hydroflux offers flexible contract options, ranging from equipment design and supply to full turnkey installations with expert execution at every stage. All projects are conducted under externally approved occupational health and safety and environmental management systems.

Our offices across Australia provide a strong local presence, ensuring seamless project management from design through to installation. Additionally, Hydroflux offers post-installation routine service contracts to maintain system performance and longevity.

Below is a 3D drawing of a recently constructed water treatment plant comprising HyDAF dissolved air flotation, sludge dewatering, multimedia filtration, Ion exchange and a range of chemical processes.

Extensive Support for Water Treatment Plants for Infrastructure

Hydroflux is a trusted partner for the manufacturing industry, providing end-to-end water treatment solutions. Beyond system design and installation, Hydroflux offers chemicals, chemical optimisation, preventative maintenance, and remote monitoring, ensuring long-term reliability and performance for every plant.

Chemical Optimisation

Hydroflux offers a comprehensive range of proprietary chemicals, including coagulants, antiscalants, acids/alkalis, oxidising/reducing agents, and proprietary cleaning and sanitising products. These chemicals are formulated to optimise process water feed conditioning before and after treatment or to enhance the performance of your wastewater treatment plant. Our chemists work closely with the project delivery team to develop a site-specific chemical program that ensures maximum treatment efficiency and cost-effectiveness.

Preventative Maintenance & Service

To guarantee consistent performance from day one, Hydroflux provides customised service and maintenance programs. Our engineers and technicians discuss preventative maintenance strategies during the construction phase, offering routine service, periodic overhauls, and full plant operation support. Our service team is available 24/7 to respond to unforeseen breakdowns, ensuring uninterrupted plant operation.

Remote Monitoring

All Hydroflux process water treatment plants come equipped with our proprietary HyCONNECT™ remote monitoring system, providing instant online technical support and troubleshooting. For remote locations with limited connectivity, we offer specialty monitoring solutions to ensure continuous system oversight. No matter where your facility is located, Hydroflux specialists are just a call away, ready to assist with real-time diagnostics and performance optimisation.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand markets and is also carbon-neutral. Click here to find out what this means for you.